If your answer was…

“No - every tool and process we have ever rolled out is being used perfectly 100% of the time by 100% of the team.” ***

then please raise your hand so the rest of the industry can study you or get a job at your company. :)

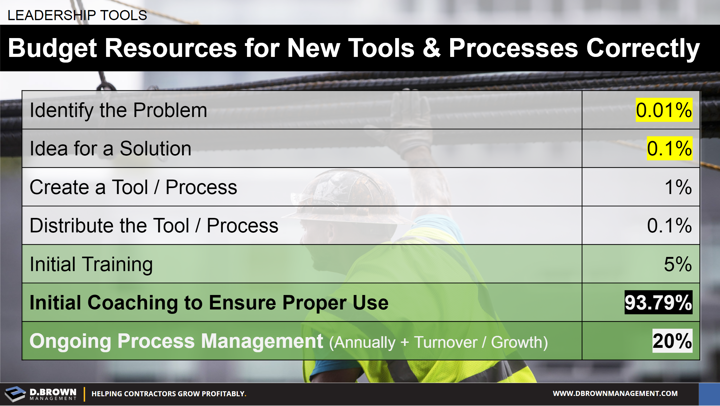

One place to look might be in how you allocate resources to solving the problem. It’s easy to get caught up in problem identification and creation as the biggest hurdles but these typically make up about 1% of the total effort.

The real effort is committing the resource for initial training, coaching everyone to minimum demonstrated competency levels and most importantly committing resources to ongoing management of the process.

If your team does not understand the level of resources required, plan for them and then have the daily discipline to stick to the commitments then you will end up with lots of tools and little impact.

This is harder than it seems and is something we spend a lot of time working with teams on: https://dbmgt.co/contact