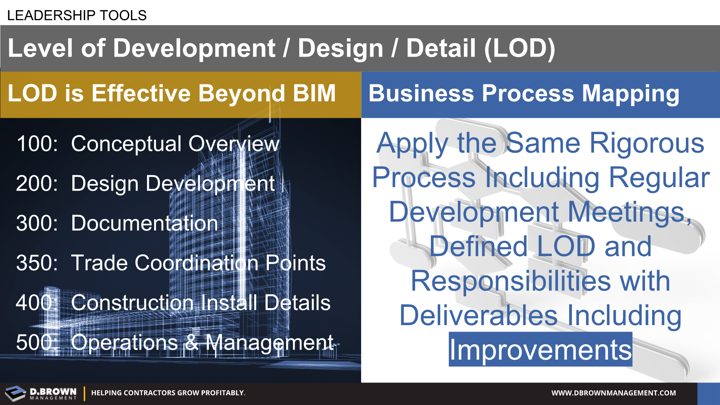

Consider how the different Levels of Design / Development / Detail (LOD) could be applied to your planning processes. Starting with a basic high-level value-stream map of how your company acquires and delivers projects to your customers. Think about a simple diagram with 10-20 components; level 100.

Now consider the series of meetings and teams you would setup on a project that will take that high-level diagram through increasingly granular design details. Consider all the frustrations of working through that design-development process going from concept to details and specifications that are fabrication / construction ready. Consider the process rigor including RFIs and change management including value-engineering.

Imagine your business with a complete set of plans, specs, as-builts, inspections and O&M manuals with training upon turnover similar to what we have on every project. That is Level 500 of the BIM standards.

What if you applied that much rigor to your business management processes?