There are many factors that go into poor productivity including:

- Unnecessary mobilizations to work areas that aren’t ready.

- Moving materials too many times or inefficiently.

- Rework to achieve the right level of quality.

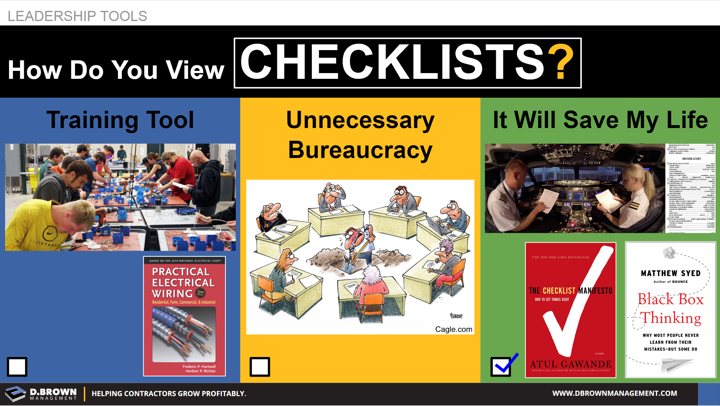

Checklists are a very simple and powerful tool that can be used to mitigate many of these problems. Checklists are also one of the most misunderstood and misused management tools. Checklists are often used so poorly that they make the problem WORSE!

- Do you deeply understand the purpose of a checklist including the history of ‘WHY’?

- Have you studied the best practices in ‘HOW’ checklists are to be used effectively?

- Have you worked with your team to develop effective checklists around the key areas in your business or on your projects where you run into frequent problems - the ‘WHAT’?

Most importantly - are you leading yourself and your team with the discipline of consistent execution; even when things get a little off-track?

It’s worth considering that the first checklists came about in the aviation industry. With over 30,000 commercial flights per day and each plane having between 367K (737) and 2.3M (787) parts there are VERY few fatal accidents. Tragically there was one in 2018 but the last one was in 2009 over 100 million commercial flights ago!

One of the most effective productivity facilitations we do with teams is to start with our Labor Productivity workshop then follow it with teams developing checklists for key areas of their projects.