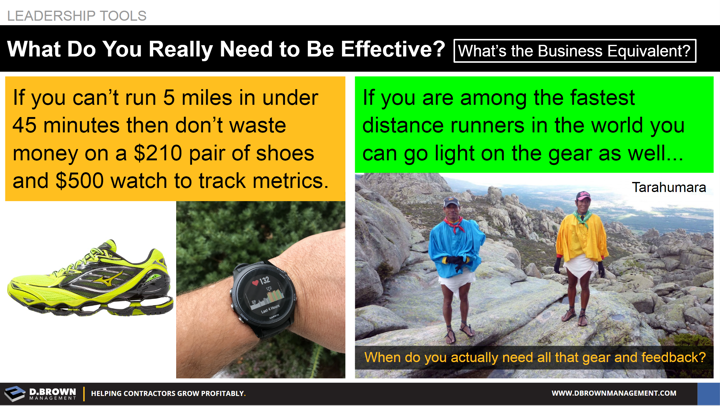

You see this all the time in weekend warrior athletes buying the best gear. If you like the gear and it gives you pleasure to have $200 shoes and a $500 watch then you should buy them but know that is why you own them.

Consider the Tarahumara who are among the best distance runners in the world. They run at high altitudes over rocky terrain in sandals!

They begin training early in life. Their diet is clean from childhood. Nearly everyone in their tribe runs - it is a way of life. When you are surrounded by people with the same behaviors you fall into them - good or bad.

- Whether you are a runner or not can you see correlations within your business?

- Do you see people asking for more feedback or better tools than necessary?

- Do you find it easier to invest in tangible tools and technology rather than the hard and unpredictable work of training people?

Buying $200 shoes is fun. Training every day and pushing your limits is hard.

Contracting is a low-margin business and every dollar counts. Make sure you are spending on the things that have the best return.