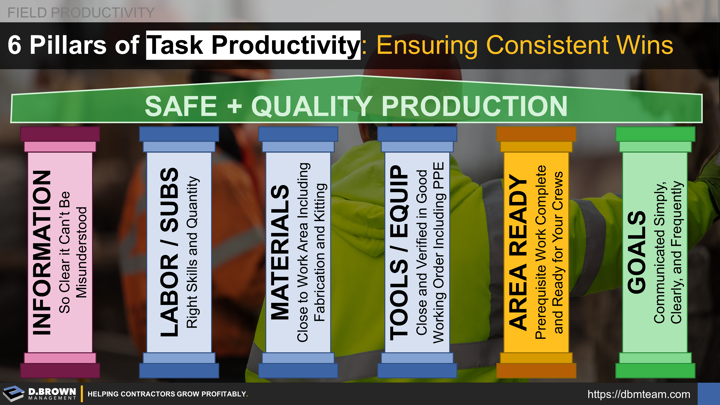

- Information: This is the starting point, information so clear it CAN NOT be misunderstood. Crews have all the information they need in order to install effectively. Ensure that this information is in the easiest to digest and most accessible format. This includes installation details with just the information required on them and that everything for this task is 100% approved before starting. With the right information and the right field leadership in place, the task will get done. This is the starting point.

- Labor / Subs: Make sure the right resources are available to execute the task. Not putting the right amount of labor resources on the task, either too many or too few, will impact productivity. Your installation detailing and planning may need to be adjusted depending on the quantity or quality of the labor resources.

- Materials: Can’t do anything without the right materials staged close to where they will be installed. Don’t start the task unless you have firm verification that 100% of the required materials are both approved and on-site close to the work area.

- Equipment & Tools: The right equipment and tools in good working order all fueled, lubed, and/or charged as required. Are these really the best tools for accomplishing this task? Is the crew competent in their safe and productive use?

- Work Area Ready: All required prerequisite work or layout by others is complete. Area is clean, well lit, and environmentally protected if required. Production in the work area will not be impacted by other trades, or it was a known condition in the estimating, budgeting, and planning process.

- Goals: Never start a task without clearly defined goals for achieving milestones, production rates, completion, quality levels, etc. Given clear information and goals, pillars 2-5 are a means to an end.

When these are integrated with Tasking the Project during the planning phase, weekly Short-Interval Planning (SIP), and ABC Daily Planning, your projects will run significantly more productively.

Learn More about how we have helped contractors integrate these pillars into their project planning, plus the weekly and daily Foreman processes with Project Manager feedback.