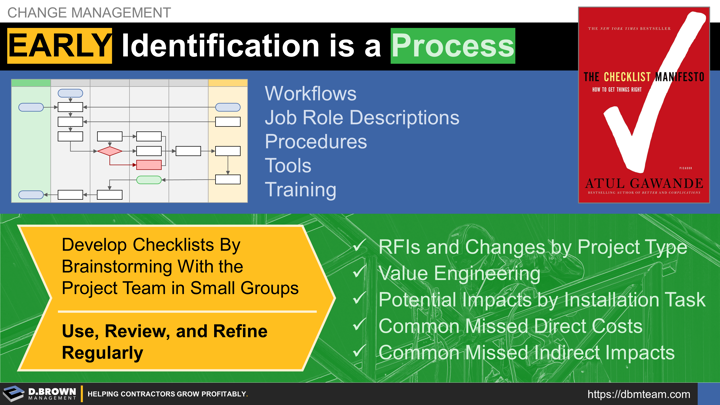

A checklist is not training - but it does reinforce training through consistent repetition.

A checklist is not a process - but it is a valuable tool for ensuring the process is executed consistently each time.

A checklist helps bridge the gap between the complexity of a task and the limits of how our minds store information.

Processes often start with simple checklists as Atul Gawande describes very well in The Checklist Manifesto where he draws connections between best practices in construction, airlines, and hospitals. Forward to 12:30 in the video.

Develop your team by building checklists for early identification of changes in small groups.

- Analyze all your RFIs for the last ____ months, identifying common elements to check for. You will see patterns. With each RFI, ask questions like:

- Could this have been identified earlier? How? By who (job role)?

- How would you categorize your RFIs into 10-15 more general categories?

- Analyze all your changes for the last ____ months looking for the same patterns you did with RFIs.

- Look at all the common tasks or installation phases on your projects. Facilitate discussions with the team to identify their top 3 most common impacts per common task or installation phase.

- What are the early warning signs of each potential impact?

- What are the most common mitigation tactics?

- Who needs to be communicated with, by when, and by who when impacts are identified?

- Look at your change order pricing in detail over the last ____ months.

- What are the most common missed or under charged direct costs? Tools? Supervision time? Commodity materials?

- What are the most common missed or under charged indirect costs? Admin time? Labor burdens?

The process of each small group building a simple checklist will develop the team.

Consolidate the lists over time to align the teams, set your standards, and continue stretching their development.

Enforce regular use of these checklists from preconstruction through estimating, project management, and field management. Continually improve them with each cycle - that is the role of management.

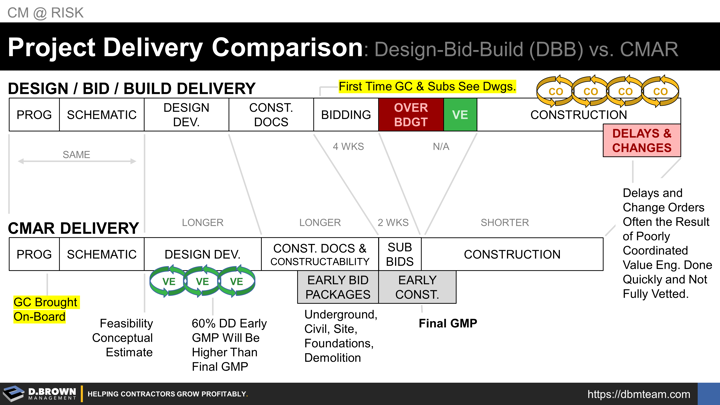

Being able to effectively do this at the preconstruction stage is a competitive advantage in many markets using alternative delivery methods. Even on DBB (Design-Bid-Build) projects, you will still be a contractor of choice by identifying changes earlier where they are far less costly to deal with.