Brief Background

The Training Within Industry (TWI) program was developed in 1940 during World War II to rapidly train new and unskilled workers in industries supporting the war effort. This included lots of industrial manufacturing, ship building, and the construction required to support those operations.

The program consisted of four training modules and was used to train about 1.6 million workers, supervisors, and managers.

- Job Instruction (JI): How to teach someone a new skill

- Job Methods (JM): How to standardize work and continuously improve

- Job Relations (JR): How to supervise and manage people

- Program Development (PD): How a company can scale 1-3 across their whole team including monitoring adoption and outcomes

The Basic Results for the United States were:

- Workforce going into 1940 was about 55 million people

- 12 million additional people joined military service primarily coming out of the workforce (about a 20% reduction in total workforce)

- Workforce grew to 66 million by 1944, a net increase of 11 million people but really the addition of a net of 23 million (12 to military + 11 growth)

- GDP (output) doubled from 1940-1944 with the workforce only increasing by 20% but with 35% of them being new to the workforce over that period of time

- Production output climbed dramatically while keeping costs relatively stable or even decreasing. For example, the B-17 (Flying Fortress) ramped up production from several per month to about one every 90 minutes while keeping the cost about $200K in 1940s dollars.

You can lookup specific metrics but in general, those are the big-picture outcomes.

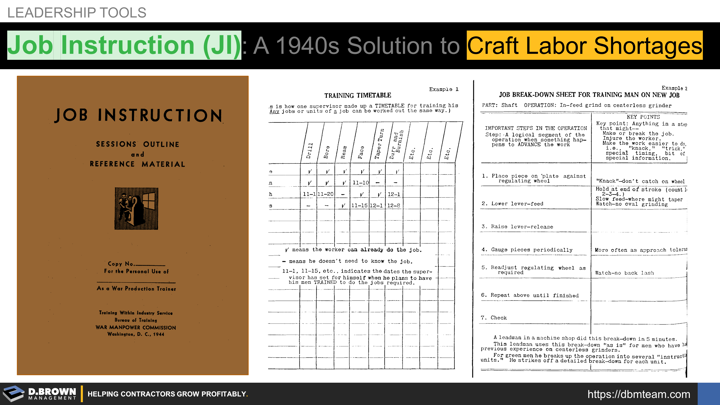

The Job Instruction (JI) Module

A 2019 analysis of the impact of all 11,575 companies that applied for the TWI program and their financial statements from 1935-1955 showed that companies receiving training on one or more of the modules had a positive impact on the businesses performance. The Job Instruction module had the biggest positive impact and enhanced the effects of the other training. Study by economists Nicola Bianchi and Michela Giorcelli.

The core of the Job Instruction method was the Job Breakdown Sheet and a four-part training methodology:

-

Prepare the Worker: Put the person at ease and make them ready to learn. Clearly explain the job's purpose, place the job in the wider context, and relate it to the worker's existing experience.

-

Present the Operation: Break down the job and clearly demonstrate each step, while explaining the key points and reasons. Go through the job slowly at first, then repeat it several times until the worker shows understanding.

-

Try Out Performance: Have the worker perform the job, while you correct any errors. Encourage questions and monitor the worker closely. This helps ensure that the worker understands and can correctly perform the task.

-

Follow Up: Gradually wean the worker off your guidance, but continue to check their performance and reinforce correct practice. Taper off assistance and correct faulty work patterns before they become a habit.

The Job Breakdown Sheet detailed each step in the job or task including key points, safety, "knacks," and "tricks" such as special timing or information. There are many other names used for something similar including:

- Standard Operating Procedure (SOP)

- Storyboards

- Work Plans / Task Plans

- Standard Work

The Job Instruction module is still used at Toyota as a foundational part of the Toyota Production System (TPS) and one key point that Taiichi Ohno reinforced was that the standard work was to be developed by the experienced people doing the work, not from a higher-level manager. The Job Instruction training reinforced this in the examples provided:

- An experienced worker in a machine shop made this break down in 5 minutes.

- The instructor uses this breakdown as-is for workers with different experience.

- For a green worker, each of these steps might require its own job break-down sheet.

Standardizing work across a company and making continuous improvements was the focus of the Job Methods (JM) training. Remember that the first step is just to be able to capture the knowledge of an experienced worker and train someone new effectively.

The other component of Job Instruction (JI) was the Training Timetable outlining all the tasks that someone needed to know in order to do their whole job effectively. This had dates for planned training and sign-offs on it certifying the worker was competent. Look up "Versatility Matrix" to learn more.

DOWNLOAD: Original Job Instruction Manual (PDF)

These are all incredibly simple but not easy to do consistently. Tools and tasks have changed but the way people learn has not.

We would recommend watching the following video made in 1944 demonstrating the training methods. They are as applicable in training today's craftsperson entering construction and using tools for the first time as they were in 1940s.

Though the video seems simplistic, please watch all 13 minutes and think about it in the context of the safety, quality, and productivity you are observing on your jobsites.

The techniques shown are the "Deliberate Practice" and "GPS Feedback" that helped John Wooden lead his team to many victories.

Reflection Questions: We recommend reading this summary, then watching the video together with your team and answering these questions individually, then discussing.

- What do you call the tool or format within your company that is similar to the Job Breakdown Sheet? If you don't have anything like it, have you seen any examples of something similar?

- Who are the 3 best trainers of crafts people in your company?

- Who are the top 3 people they have each trained?

- What are the similarities and differences in how they teach others from green through apprenticeship on the job? Between each other and from the techniques shown in this video.

- What are the 10 tasks performed on the jobsite that would benefit the most if a large percentage of your field workforce did them consistently, safely, and productively with the right level of quality?

- What would it look like if all your foremen and crew leaders were trained in this method of training others? Even if only 70% adopted it, what would the impact be over the next year?

- What other roles and tasks could you see something like this applying to? Consider roles like PM, PE, Estimator, etc.

There are plenty of other aspects to solving the construction labor shortage at both the craft and management levels. Please contact us to learn more.