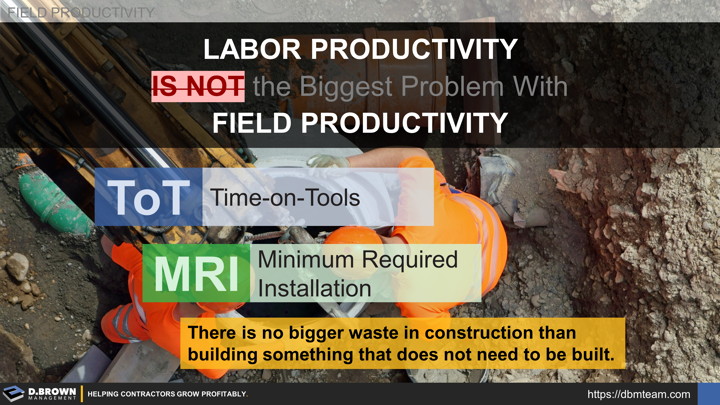

- Maximize Time-on-Tools (ToT): Ensure that crafts people spend most of their day working with their tools actually installing things. Different studies place the industry average between 50-65%. Leverage the 6 Pillars of Productivity and ABC Daily Planning.

- Minimum Required Installation (MRI): Don’t take critical shortcuts but don’t over-build the project. In the field we would call it “Gold Plating.” Effective installation details, craft training and good field supervision practices will ensure that you get the right level of quality.

- Minimize Rework: The only greater waste than installing more than what is required is doing it twice.

General Contractors and Project Owners can do a lot to set the conditions for success with their labor-intensive subcontractors.