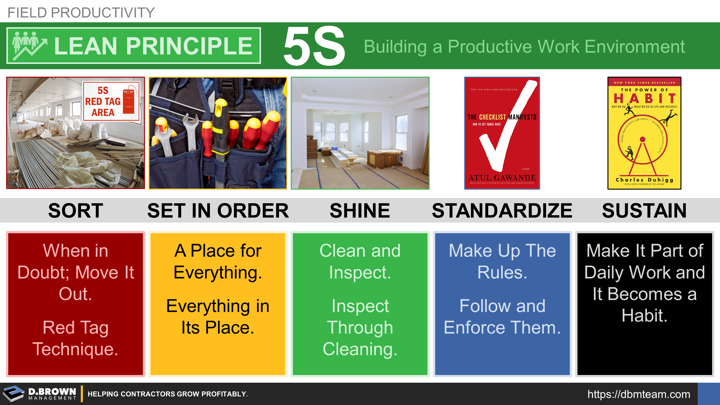

The concept of 5S is about the daily habits and tools to create a productive work environment that is continuously improving.

- SORT: Only keep what you need (material, tools, information, etc.) in the work area and inventory. When in doubt, move it out. Use the Red Tag technique as part of your sorting process.

- SET IN ORDER: May also be called straightening and the work is organizing everything into its place. Productivity starts with having a defined place for everything and putting everything in its place.

- SHINE: Clean and inspect the work area including the tools, equipment, files, etc.in the work area.

- STANDARDIZE: Standards are the basis for all training, feedback, and improvement. Standards often start with simple checklists as Atul Gawande describes very well in The Checklist Manifesto where he draws connections between best practices in construction, airlines, and hospitals. Forward to 12:30 in the video.

- SUSTAIN: Moving from one-time tasks to routine habits, management, and ultimately into the culture of the company. Continuously improving safety, quality, and productivity are as much about culture as they are about process and management. Charles Duhigg describes both the science and tools in The Power of Habit.

5S can be applied to your kitchen, garage, service van, work truck, gang box, storage container, desk, computer, warehouse, etc. Wherever your personal work area is you can apply 5S.

If you do it once as if it were a major project, then it won’t do anything besides put you behind schedule.

If a 600-calorie breakfast + 30 minutes of stretching and exercise is a good morning routine, then you would never say:

“Once per month I’ll workout for 15 hours and eat 18,000 calories so I can save time all month.”

- Make 5S a habit for yourself.

- Engage your team.

- Align the times when you do your 5S.

- Share your results - good and bad.

- 5S isn't just for the shop or jobsite - it's for the office down to your computer and mobile phone.

- 5S isn't just for work - it will make a huge difference at home too.

Learn more from Paul Akers and 2-Second Lean which is a great very short read with lots of pictures available in both English and Spanish.