Everything discussed is about major changes such as those linked to strategic decisions, major changes to the contractor business model, or integration of an acquisition. These often come at inflection points as a contractor is navigating the different stages of growth or during succession. Examples include:

- Separating the functions of Project Management, Field Management, Purchasing, and Estimating into different roles with different management structures while maintaining the information flow that keeps them all aligned.

- Separating out Virtual Construction and Fabrication as support functions including the different cost structures for each (Accounting) and integrating them fully with Estimating, Field Operations, and Project Management.

- Standardizing Field Installation practices across the company and integrating them with Virtual Construction, Fabrication, and Estimating.

- Adding Design and Engineering services while shifting project delivery methods toward CM at Risk, which requires completely different approaches to Business Development, Preconstruction, and Project Management.

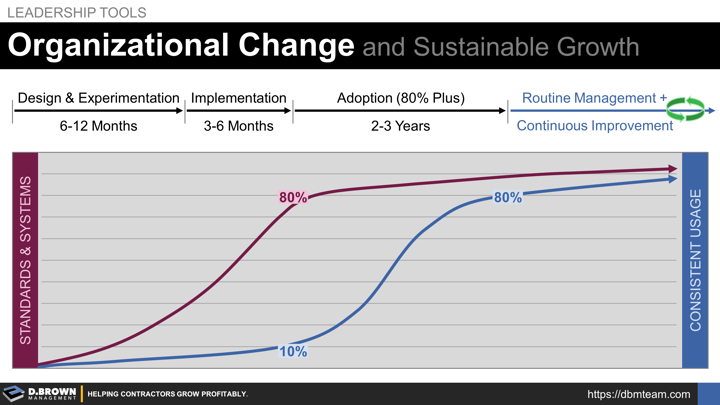

These are all multi-year initiatives that require support and deliberate management from all top leadership. Below are the basic steps and guidelines.

- Select a cross-functional team to work on the initial design and experimentation phase. Pick people who are both on the front-side of the Diffusion of Innovations Curve who have a combination of capabilities, including:

- Strong desire for what this change is.

- Communication skills.

- Technical skills as they relate to this change.

- Respect from top leadership and management.

- Enough direct control to be able to run experiments on their own projects and with their own teams to verify proof of concept.

- Select a handful of test projects that account for around 10% or so of the total company. These should be under managers who are not part of the core design and experimentation team but do fall into the "Early Majority" on the change curve. The objectives at this stage include:

- Disciplined feedback loops to rapidly improve the standards and systems taking them to the 80% range.

- Measurement of the outcomes to set the stage for broader adoption across the organization. Remember that "Not everything that counts can be counted and not everything that can be counted counts." - William Bruce Cameron.

- Decision from leadership on whether to push forward with broad adoption, go back to design, or kill the initiative.

- Moving toward the adoption stage requires several key components all working together:

- Clear and consistent communication from top leadership about the direction, the rationale (why), and what success looks like including adoption milestones and results.

- Management systems for all levels involved including:

- Clear responsibilities and accountabilities by job role.

- Adjustments to related processes as required.

- Quality Control (right outcomes) and Quality Assurance (right process) procedures and operating rhythms defined for managers at all levels who are involved.

- Information systems to track adoption and outcomes.

- Feedback systems and escalation paths to handle problems and improvement recommendations.

- Adoption plan including training focused on the optimum sequencing for impact. This will include evaluation of both the people and the projects for a balance of:

- Where they fall on the Diffusion of Innovation curve.

- Where they fall in their technical capabilities.

- Where they fall in their ability to lead change, influence others, and manage.

- Where the project(s) fall in terms of impact from these changes (if successful).

- The final stage of Routine Management and Continuous Improvement looks similar to the prior stage, but at this point, everyone has adopted the change as "Self-Evident," and those leading the adoption across the whole organization can move on to the next change.

Don't underestimate the negative impact if leadership isn't fully bought into the changes. Even one outlier on the leadership team will have a huge impact across the whole organization. Remember the diffusion and multiplication effect of communication.

Don't try to maximize the quality of the design in the early stages. Frank Blake who is the retired Chairman and CEO of Home Depot described it simply in the formula E=QxA. Effectiveness equals the Quality of the idea (strategy, standard, system, etc.) multiplied by the Adoption across the organization. 90% quality that is only 20% adopted is far less effective than a 70% idea that is 90% adopted.

Know the value and the limits of an unbiased but experienced 3rd party. There are three critical points where they can add a lot of value.

- Executive advisory for identification and selection of the priorities to focus on.

- Outside technical and process expertise during the Design and Experimentation phase.

- Leadership development coaching around organizational change.

You cannot delegate or outsource change at this level.