Case Study: Two Superintendents Building Identical Projects

Example from David Brown - personal experience as a Crew Leader and Foreman for the Electrical Contractor on both projects.

In 1990, there were two identical projects being built by the same project owner. The only variations were some site-specific adjustments around parking and drainage.

- Two different General Contractors were selected - one for each.

- About half of the Specialty Contractors were on both projects.

- The projects started in the same month.

- One of the GC Superintendents was in his early 60s and very experienced.

- The other GC Superintendent was in his late 20s and it was his first project.

The experienced superintendent was confident is all decisions made and able to solve problems as they came up very quickly. His project meetings were well run and ended with clear direction. In the first few weeks of the project, he had already accelerated the schedule.

The inexperienced superintendent would gather all the trade Foremen in his trailer nearly every day and have us all stare at the project schedule on the wall. He kept a notebook in his vest and would go to each foreman and ask, "What do you need?" He would ask lots of technical and coordination questions from each foreman. He was learning. He took lots of notes. He often came out during the day to ask more questions, often interrupting work being done.

All the Specialty Contractor Foremen and PMs were heavily concerned about his level of inexperience, with some addressing it formally with delay notices, RFIs, etc. Most just talked about him behind his back.

Fast forward 18 months to the planned completion of the projects.

The less experienced Superintendent who started their project much slower finished three months ahead of the more experienced Superintendent, with less change orders, and with higher profitability for the trade contractors that discussed it.

What had happened was that when the experienced Superintendent got to the point in a project where there are a lot of smaller conflicts to work through, he became overloaded. He was the bottleneck. Compounding that challenge, he didn't adjust his management style, instead continuing to direct but often without full context and coordination leading to more rework and changes.

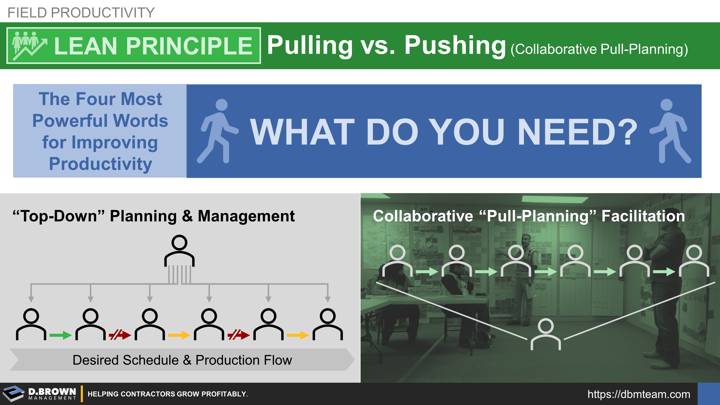

Looking at this story today, you would say that the inexperienced Superintendent was "Pull Planning" so what's the big deal?

Remember that this was 1990 and the term lean was only starting to enter people’s vocabulary in car manufacturing based on a paper written by John Krafcik in 1988 (Triumph of the Lean Production System). It wasn’t until 1997 that the Lean Construction Institute was founded, and their flagship tool called the Last Planner System was introduced.

Google indicates that the term didn't start being used widely in books until 2007 with some months in 2007 still having zero searches for the term and interest continuing to rise through 2023.

This brief history is only provided to illustrate that "Management Systems" such as the Last Planner System (LPS) and its components like Pull Planning are really just codification of best practices in a way where they can be easily replicated by others. These systems become increasingly more complex and valuable as both projects and contractors grow in size.

The inexperienced Superintendent went on to grow in his career through many different roles in the company including Project Manager and Preconstruction, and eventually to Vice President.

Learn more about basics of Pull Planning on a construction project with these two videos from Jason Schroeder (Elevate Construction) and Jason Mayes.

Note that effective Pull Planning requires a culture of collaboration, problem solving, and learning. Brent Darnell has been focused on Emotional Intelligence in the construction industry since 2000. If you want a quick laugh about something very critical, check out this out.

Beyond the construction project, think about the concepts of Pull Planning as applied to your business processes. Imagine work flowing smoothly from your strategic decisions through your hard-won customers and throughout each functional area of your business.

Final note on projects and business - don't think about "Top-Down" planning and management as being opposite of Pull Planning. They both have their place and must work together as an integrated system.

We exist to help contractors build stronger businesses for the next generation.

All relationships begin with a simple conversation.