Excellent advice from the book Tribe of Mentors that is the culmination of hundreds of interviews over years with the highest performers from across multiple industries.

This advice can be applied to the hiring and management process:

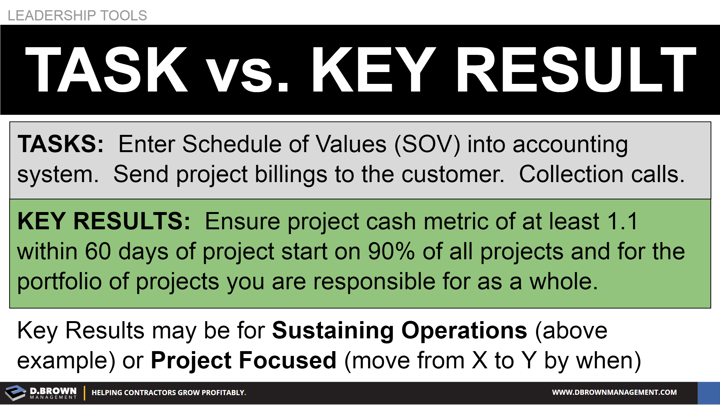

- Build very clear job descriptions around specific Key Results that you need to achieve instead of a list of vague tasks.

- Will you be able to tell if the team member is achieving the Key Results or not?

- Assuming the Key Results are achieved by the team member; will they have a quantifiably positive impact on the business?

- Build a detailed Interview Guide prepared for the position with specific questions defined for each of the Key Results so you can identify the best candidate for the position?

- Consider the impact if this specific use of language permeated your whole organization. “Go to the second floor and install lights.” vs. “There are 3 conference rooms on the second floor. Please have them all of them lit and ready for inspection by 2PM today. The inspector will meet you there at 2:30 and we need them signed off.” Which Foreman would you rather have laying out your crews?