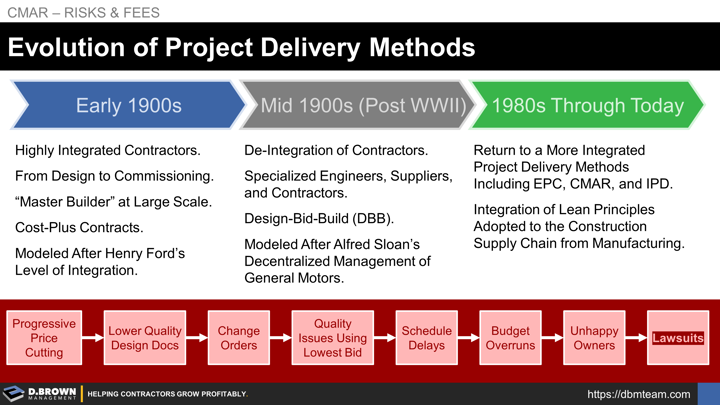

The early 1900s was a time of major industrialization which required highly integrated contractors who could take a project from design through commissioning. They were "Master Builders" at a very large scale modeled after Henry Ford's level of integration. Most of the contracts were cost-plus with a heavier focus on schedule - this was part of the project owner's strategies and business models at the time which depended heavily on being first-to-market. Ford's River Rouge project was a perfect example of this type of project.

The mid-1900s post WWII brought in a focus of specialization and cost controls as many industry sectors and companies reached maturity. Their strategies and business models from first-mover advantage toward stability. The construction industry as a whole followed with the de-integration of contractors towards more specialized engineers, suppliers, and contractors. This was modeled heavily after Alfred Sloan's decentralized management of General Motors and the Design-Bid-Build (DBB) project delivery method became widely used.

Strategic Choices - Being the Exception

It's worth noting that industry wide inflection points like this create both great turmoil and great opportunities for contractors. Bechtel is a great example of this having started in 1898. Post WWII, Steve Bechtel Senior adjusted their strategy to focus on services where they were working with select customers as much as for them. They also positioned for the global energy boom following the war.

This continued with Steve Bechtel Junior who urged Bechtel's board of directors to agree to a "Triple Ten" strategy following the Atomic Energy Commission Act of 1954 where they would commit ten percent of its pretax profits and ten percent of its management and engineering capabilities for ten years to learning the technology of nuclear power.

By the mid-1970s, Bechtel could develop the concept for a project, perform feasibility studies, help arrange financing, perhaps invest some of its own money, do the engineering, and either perform or manage construction. See Bechtel's Philosophy on Business Development.

Study the past to help make decisions about the future: Bechtel - Building a Century (1898-1998)

This is just an example of how critical strategic choices are for contractors.

For the industry as a whole, this relentless focus on cutting costs led down a path that ultimately created a whole new set of problems:

- Progressive price cutting led to...

- Lower quality design documents led to...

- Increases in change orders and quality issues when using the lowest bid often leading to...

- Schedule delays and budget overruns leading to...

- Unhappy project owners and contractors leading to...

- Lawsuits

The 1980s through today started to see a return to the more integrated project delivery methods from the early 1900s with some new twists based on lessons learned. These methods include:

- Construction Manager at Risk (CMAR) which has become the preferred delivery method for the ENR Top 400 contractors, providing many advantages over Design-Bid-Build (DBB).

- Engineering, Procurement, and Construction (EPC)

- Integrated Project Delivery (IPD)

- Design-Build (DB)

- Public-Private Partnerships (PPP)

Many project delivery methods and project management are incorporating lean principles adopted to the construction supply chain from manufacturing.