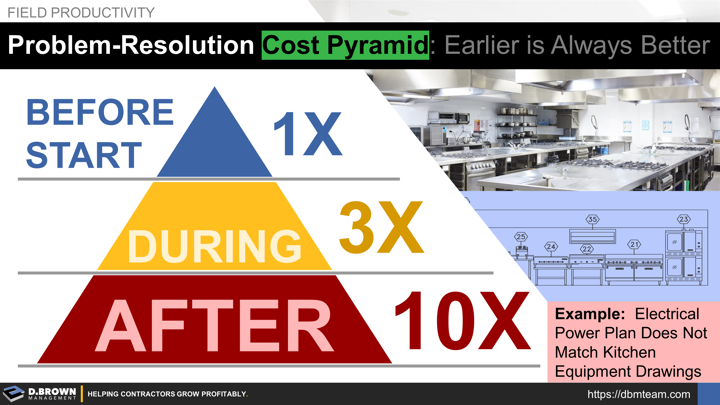

To illustrate this, we will use a common example of a commercial kitchen equipment plan not being fully coordinated with the electrical plans.

A piece of equipment requiring a dedicated circuit is shown on the panel schedule but not the power plan so it was easy to miss in the estimate. When the problem is identified determines the total cost of fixing the problem:

- Before - some plastic conduit run under slab, some wire, and a couple hours (max) of time.

- During - more expensive metal conduit run overhead and 6-8 hours of time.

- After - remobilization time to the work area, protection for finishes, working above hard lid ceiling, etc. plus the customer is likely frustrated.

The cost of the problem is the cost of the problem (1X). Finding it ahead of time minimizes the costs and maximizes customer satisfaction. Finding it during construction will cost about 3X and after construction 10X+.

What systems do you have in place to find problems early? Create a checklist by phase of work that helps identify potential problems early.

How many problems did you have last month that could have been found earlier? Study all your RFIs and Change Orders for the last month. Could they have been identified sooner? Put those items on your checklists (above). Repeat each month with your top PM, Estimator, and Field Leader. You will be surprised at how quickly you improve profitability and customer satisfaction while lowering stress. Contact us to schedule time to talk about how we have approached this in the past. We will freely share all lessons-learned, both the good and the bad.

Early identification is a trainable skill and a workflow process including checklists.