Materials are one of the six pillars of productivity. As a contractor grows, the challenges associated with purchasing compound, but so does their leverage with the supply chain and potential for substantial positive impact. Our experience shows that contractors frequently underestimate the full impact that purchasing can have on all areas of the business leading to underinvestment and poor results.

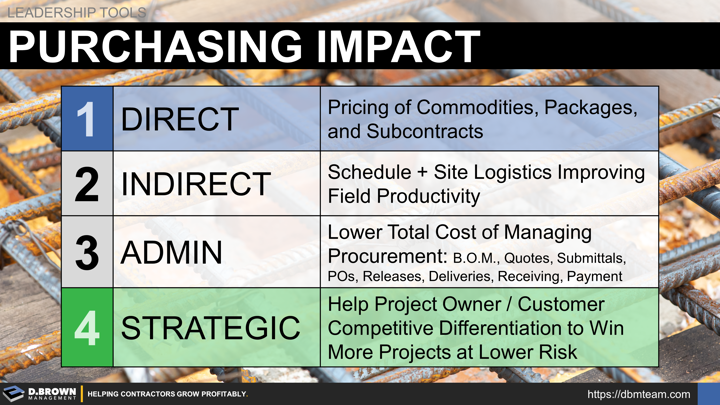

The impact of purchasing can be broken down into four major categories:

- Direct: The price paid for everything from commodities to major packages to subcontractors is the easiest impact to see.

- Indirect: Improving or at least not negatively impacting the project schedule. Improving field productivity by improving site logistic details from the point of receiving them until they are in the hands of the craftsperson doing the installation.

- Admin: Lowering the total cost of managing the entire procurement process. Consider every step required to support material ordering from the multiple quantity take-offs required to get to a bill-of-material (BOM) through getting quotes, submittals, negotiating prices, writing the purchase order (PO), releasing the materials, tracking them, deliveries, receiving, lien filing and releases, and payment. This is not an insignificant cost. Lack of effective workflows, technology, and quality control (QC) will often increase costs while introducing costly errors.

- Strategic: Leveraging relationships and know-how to help the project owner build their project which creates a competitive differentiator helping the contractor win more projects including negotiated work.

Note: If you are a general contractor or construction manager, you may be able to help your subcontractors improve their purchasing processes which will only make your projects run smoother. Gilbane is an example leveraging their supply chain capabilities to help their customers, subcontractors, and sharing some of that information more broadly. See their supply chain report in our OpEx Benchmark list.

How would you evaluate how effective your company is within each of these categories? 0-10 scale with 10 being at a point where you can't see any significant improvements.

If your purchasing is decentralized, evaluate the different people or teams separately. It's the average score that impacts the company overall.