How effectively teams investigate these largely determines the trajectory, sustainability, and profitability of their growth.

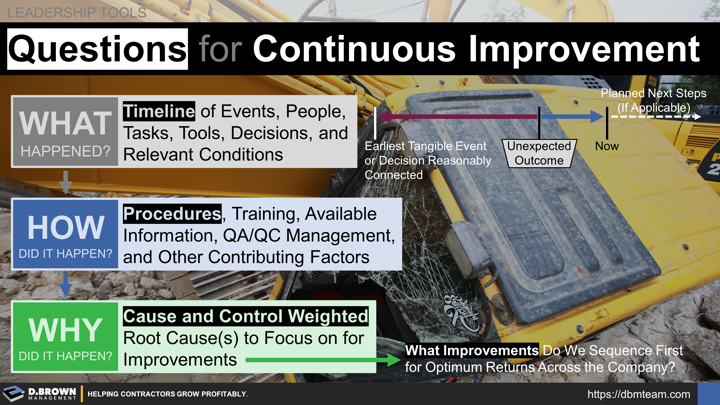

Formulating and then asking good questions in the right sequence and with the right group of people is a huge part of the continuous improvement process. Below are some questions that can help you get started:

Helpful Definitions and Vocabulary

- Standards (Expected Outcomes): These may be subjective tribal knowledge or explicitly defined. Many standards usually have a target and a high/low tolerance range. Your safety, project plans, and company business models rely on these standards being consistently met which is where workflow processes, procedures, training and managing including Quality Assurance (right process) and Quality Control (right outcomes) work together to create predictable outcomes.

- Unexpected Outcome: Anything falling outside of the standards. While it is easy to fall into the habit of only investigating negative deviations from standard, there is just as much to be learned from studying where standards have been exceeded. Examples of undesired outcomes: failure, anomaly, schedule delay, broken equipment, missed production, product defect, problem, close call, mishap, etc.

- Proximate Cause(s): The event(s) that occurred, including any condition(s) that existed immediately before the undesired outcome, directly resulted in its occurrence and, if eliminated or modified, would have prevented the undesired outcome. Also known as the direct cause.

- Root Cause(s): One of multiple factors (events, conditions or organizational factors) that contributed to or created the proximate cause and subsequent undesired outcome and, if eliminated, or modified would have prevented the undesired outcome. Typically multiple root causes contribute to an undesired outcome.

- Root Cause Analysis (RCA): A structured evaluation method that identifies the root causes for an undesired outcome and the actions adequate to prevent recurrence. Root cause analysis should continue until organizational factors have been identified or until data is exhausted.

- Immediate Countermeasure(s): Short-term actions taken to mitigate the unexpected outcome but they are likely not systemic changes that will consistently improve future outcomes across the project, company, and industry. Also called fire fighting. Countermeasures are critical for both safety and to keep things moving forward but are not long-term solutions.

The Unexpected Outcome: Occurred or Noticed - The Immediate Countermeasure(s)

- Is everyone safe?

- What do we need to do immediately to mitigate, if anything? (countermeasures)

- Who do we need to communicate with? Escalations and involvement

Should We Do a Deeper Investigation?

- How frequently has this unexpected outcome occurred in the last 12 months?

- What is the average cost per occurrence? Note that not everything has a cost that can be easily quantified such as safety or reputation.

- Do we have the right people with the right capabilities, motivations, and authority to work on this investigation?

What Happened Questions - Building the Timeline

Please do not shortcut this step. In our experience, most improvements are identified just by doing a thorough job on developing a timeline. The timeline of events is the objective reality that everyone can continuously go back to. There is no subjectivity to the timeline - just what happened and when laid out in a sequence.

Assumptions and "should have" discussions need to be kept out of the timeline creation. Talk to the people with first-hand knowledge. Look at records of what occurred including daily reports, emails, phone logs, or other tangible documents.

About the Timing Immediately Around the Unexpected Outcome

This may be a specific event or the recognition of an outcome that was a cumulation of multiple events over time. Not all the questions will apply to every situation.

- Please describe the unexpected outcome in detail from your perspective. Ask each person directly involved to do this and ask the additional questions below to help fill in the details.

- When did the unexpected outcome occur?

- When did you first know about it and how did you find out about it?

- Who were the people directly involved and what were their roles?

- Were there any other people indirectly involved?

- What specific task(s) were being performed?

- What specific tool(s) were being used?

- What records can we look at that are related? Video, documents, communications, etc.

- How would you quantify the unexpected outcome? If applicable. If this relates to a standard of performance, is it an explicitly documented (in-writing) standard, or accepted tribal knowledge? If this is explicitly documented, find it and review together to ensure everyone is on the same page. If it is accepted tribal knowledge, ask several people to describe their understanding of the standard to put the quantification in context.

- What were the relevant conditions that existed during this time? Weather, lighting, schedule, stress, fatigue, etc. These may be individual, team, project, or company related. These may be different for different individuals.

Remember that this is just the "what" stage - not the "how" or "why" stages. This is not the "improvement solutions" stage. This is just information gathering and laying it out on a timeline.

About the Immediate Countermeasures:

This is about developing the timeline up to now and any planned next steps if applicable. Understanding, sharing, and improving how teams immediately react to unexpected outcomes is just as valuable as developing root cause solutions.

- Did this unexpected outcome require immediate countermeasures?

- Are those complete? If so, what was the outcome? If not, what are the planned next steps.

- Please describe everything that happened in sequence from the unexpected outcome (above) until now. Utilize many of the same questions from above that were used to understand the unexpected outcome.

Timeline Leading Up to the Unexpected Outcome:

This portion of the timeline lays out all events, people, tasks, tools, decisions, and relevant conditions working backwards from the unexpected outcome to the earliest tangible event or decisions that is reasonably connected. The facilitator's role is to keep this portion of the discussion on-track and determining what "reasonably connected" means in the context of this specific timeline.

This is similar to "Pull-Planning" in the flow and questioning except is focused on understanding history rather than planning forward.

- What happened just before the unexpected outcome? Events, tasks, decisions, etc. Use a combination of questions 1-10 above from defining the unexpected outcome to fully understand.

- Repeat the series of questions iteratively until you have developed a timeline all the way back to the earliest event or decision that is reasonably connected.

At this point, you should have a clear timeline of what happened. Everyone on the team should see it the same way. There should not be any subjectivity to this timeline - it is just factual. The facilitator's role is to keep the emotion out of it to the fullest extent possible.

Special Note (Emotions): Emotions are normal, especially when working through a negative unexpected outcome. Acknowledge this and if appropriate at certain times, use the following questions.

- How are you feeling now? Please just focus on the emotions you are feeling. Don't comment on why you are feeling that way. Just take a moment to acknowledge them. A list of emotions can be helpful to focus people.

- How were you feeling at that time?

Remind others to not comment on or question emotions that a person was feeling. This is just a process of acknowledging them which is important.

Acknowledge the emotions but don't dwell on them. Move the conversation back to the objective timeline.

How Did It Happen Questions:

Use the timeline as reference and ask this series of questions for each point on the timeline as applicable. Please remember that these are all just factual questions. This is not about assignment of blame or jumping to a solution. This is just about gathering the information about what is there.

- What is the procedure for doing the task or making the decision?

- Is that procedure explicitly documented or is it tribal knowledge? If it is a written procedure, go look at it as a team. If it is tribal knowledge, have someone explain their understanding of it in detail - step-by-step to ensure everyone understands it the same way.

- Was the procedure followed?

- Is there training and/or certification for doing that task or using that tool?

- Did the people involved have that training or certification? If so, when?

- How frequently had the person or persons done this task or made this decision previously?

- When was the last time this person or persons had done this task or made this decision?

- What was the information that was available at that time to the person(s) doing the task or making the decision? Go look at the actual information including plans, specs, contracts, etc.

- What were the QA - Quality Assurance (right process) and QC - Quality Control (right outcome) management tasks associated with the task, if any?

- Are the management procedures for QA/QC explicitly defined or tribal knowledge. If it is a written procedure, go look at it as a team. If it is tribal knowledge, have someone explain their understanding of it in detail, step-by-step, to ensure everyone understands it the same way.

- Were the QA/QC procedures followed?

- Were there other contributing factors not already covered?

Why Did It Happen - Getting to the Root Cause(s) Questions:

You now have a clear, detailed, and objective timeline. Usually, the root cause(s) are clear by now but if not, it is important to ask these questions.

- Impact Weighting: If everything else remained the same but we changed just this one thing, to what degree would that impact the unexpected outcome? You are looking for the items that have the biggest impact on the unexpected outcome. There are probably 1-3 items that have the majority of the impact on the outcome.

- Grouping: What are the similarities between the details identified? For example "unclear procedures" or "procedures not followed" may show up multiple times.

These are just starter questions. Develop your own organizational guidelines for these. There is no substitute for practice and experience.

Please contact us to talk through your particular situation. We will share freely any lessons we've learned to help you improve your contracting business.