What if you could shift 5% of the time spent on logistics to installation while accelerating your foreman development?

Depending on the work study only 50-64% of the work hours are spent on actual installation or “Time-on-Tools”.

For a $50M per year specialty contractor with labor being about 35% of their job costs this is a savings of OVER $1,000,000 per year.

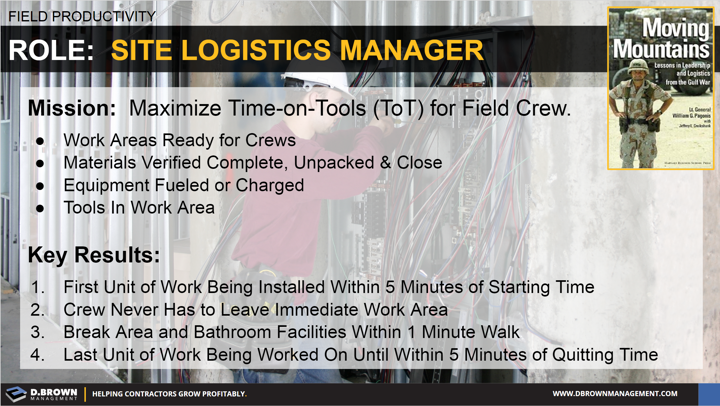

Consider changing the role of “Material Handler” being an entry-level person to a role of “Site Logistics Manager.”

Fill this role with a high-potential crafts person who has already demonstrated capabilities as a lead person overseeing a few people. This is a role they will fill before being given their own job to run.

They have 100% accountability for 3 of the 6 pillars of productivity:

They serve as the “Right Hand” and “Second-in-Command” to the Foreman, General Foreman or Project Superintendent who focus on the other 3 pillars of productivity:

- Right labor scheduled to the right areas of the jobsite.

- Given the right information for an effective install.

- Clear production goals set and managed.

The military assigns Generals to run logistics. Why do contractors typically assign entry level people for something that eats up 20% of the labor?