Technology now touches nearly every task a contractor performs from recruiting and talent development through business development, estimating, design, fabrication, project delivery, and ongoing maintenance of the facility.

There are now hundreds of specialized technology tools that can be implemented by contractors and each add individual value. But the true value comes from integrating this technology together with effective workflows and the right team of people.

Contractors build competitive advantages when they leverage technology and talent to integrate workflows across functional areas in their business. Ultimately, the workflows can be integrated across multiple companies in the supply chain to unlock maximum value.

Look at the example of a purchasing process and six different levels of integration starting with relatively simple implementation through supply-chain integration:

- Write a Purchase Order > Receive Material > Receive, Approve & Pay Invoice

- Mobile Updates to Field on Materials + Mobile Receiving

- Tie Purchase Order to Standard Parts Database with Pricing

- Virtual Construction Modelers Receive Instant Feedback If a Long-Lead Item is Designed

- Proposed Purchase Order or Release Created Automatically from VC Model

- 2-Way Data Exchange with Suppliers for Pricing, Inventory, Ordering and Billing

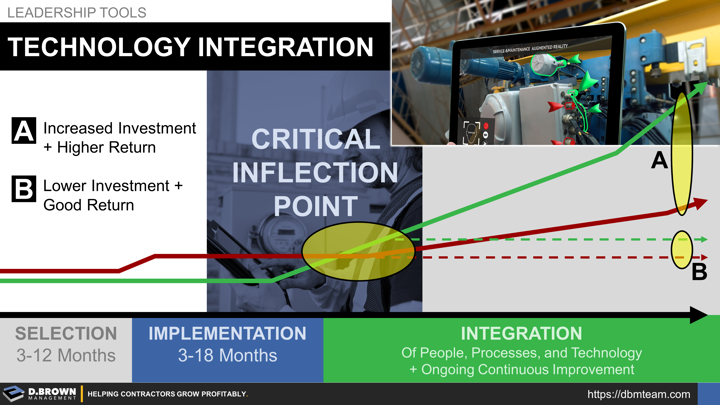

Once new technology is implemented, contractors are faced with a critical choice that dramatically impacts their return on investment as well as their competitive advantage:

- Continue investing in time, training, technology and integration despite the many challenges and constantly changing landscape. There is more risk with this route and substantially more upside as well.

- Taper off investment after the implementation is complete and you are receiving a good return on your technology investment.

Effective implementation and integration start with a rigorous selection process including knowing the current-state workflow and a roadmap toward a pragmatic future-state based on current size of the company, strategic decisions, and the team's comfortable capabilities and capacity.

- How do you think about technology?

- How does your team think about technology?

- How effective have you been at truly integrating technology to streamline your workflows?

We exist to help contractors build stronger businesses for the next generation by leveraging talent, technology, and capital through alignment and transparency.

An experienced and unbiased 3rd party can bring valuable perspective and specialized skills to help you choose, implement, and integrate your technology tools more effectively.

All relationships begin with a simple conversation.