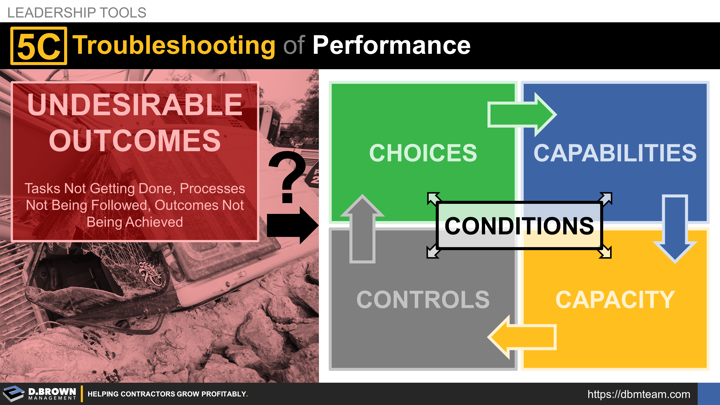

Troubleshooting starts with asking a series of good questions, sometimes to yourself (thinking) and sometimes to others to help increase depth of understanding for all involved.

Undesirable Outcomes (Individual)

- Tasks are not getting done

- Processes not being followed

- Expected outcomes of the process not being achieved

Interrelated Questions to Troubleshoot

Outcome Expectations, Undesirable Outcomes, and Trends

- How frequently has this type of undesirable outcome (miss) occurred with this individual and for the whole team? Sometimes a miss is just a miss. What does the trend of misses look like?

- As compared to what? For example: safety incidents versus hours supervised.

- How much clarity did you have around the outcomes you expected, including the level of quality, productivity, deadline, process, etc? Were they S.M.A.R.T.?

- Was their role description clear and is it still relevant?

- Were the expectations set explicitly in writing or implied verbally or otherwise?

- On a scale of 0-10, how confident are you that they clearly understood what was expected?

- Did you use good control processes such as back-briefing to ensure clarity?

- Tasks and decisions that need to be done/made?

- The process (workflow, value stream, etc.) that sequences those tasks and decisions in a way that most consistently will lead to expected outcomes?

- The procedures on how to do each task or make each type of decision including tools used, subject matter experts (SMEs), the directly responsible individual (DRI), the manager who is accountable, and others involved?

Capabilities - Including demonstrated skills and raw capabilities that are undeveloped

- Did they have the know-how to do this task?

- How do you know they had the know-how?

- Did they tell you they knew how? Self-evaluation.

- Did they have some sort of certification, either external or internal that they are capable?

- Have they demonstrated capability before in doing this type of task?

- All memories and capabilities fade without routine use - when was the last time they performed this group of tasks or made these decisions individually and as a team successfully?

- Did they have everything they needed, including tools, materials, work area, etc.

- If it is a capability gap, can it reasonably be closed with training and practice? Be intellectually honest with yourself and them if you don't believe the gap can be closed with training and practice. Not all performance problems can be fixed with accountability and training.

Capacity - Don't mistake a capability or choice problem for a capacity problem.

- Did they have the capacity to get this task done, considering everything else currently on their plate? This is especially difficult to assess for roles that serve multiple other people or customers. If it seems they aren't prioritizing well, it could be that they have difficulty saying no to anyone, which is a common occurrence for people in these roles.

- Has anything else changed in their workload?

- Are there other things going on outside of work that are eating up their physical, mental, or emotional capacity?

- Do your management systems for resource planning help people identify when they are working beyond their comfortable capabilities or capacity? It is often very hard for any of us to see ourselves objectively.

Controls

- What is the condition of the standards for performing the series of tasks and decisions in this process?

- Subjective judgement of good/bad and implied how-to procedures? This is where everything starts and there is nothing wrong with this starting point.

- Metrics clearly defining the expected outcomes?

- Procedures documenting specifically how to perform the tasks or make the decision?

- Variability ranges on the expected outcome metrics? All processes have tolerances and there is dramatic increase in the cost required to tighten tolerances so that must be balanced out with the cost of the variability. Working past the point of diminishing returns can eat up profits and increase stress very quickly.

- Workflows (process, system, value stream) showing the connections between all the tasks, decisions, and roles? This ultimately leads to the capability that is aligned with the company's strategies providing competitive differentiation.

- Management systems including resource planning (right capacity), QC (right outcomes), QA (right process), and PDCA (continuous improvement)? A management structure is related to, but is not the same as a management system. If you are not extremely clear about the managerial tasks required to keep a process on-track, that is likely a control area to look into.

- Is there a clear escalation path if there are problems?

Choice - Both conscious and subconscious

- Did they choose to run an experiment to improve on the process and just fail to communicate it? Good experiments will deviate from the standard process and will often fail. Without good communication, an experiment can look like a missed outcome.

- Did they choose to move forward with the task without total clarity on the expectations and process?

- Was it driven out of insecurity on their part, a broader cultural issue stemming from intense management, a combination of the two, or something worse like a "Kill the Messenger" style of management?

- The final question is whether they deliberately chose to not do the task as expected with the follow-up questions being:

- Do they not have the right level of desire to do the required work?

- Do they not have the emotional temperament and discipline to do it anyway?

Conditions - Choices, capabilities, capacity, and controls all occur in the context of conditions. Not all of these questions are applicable to every situation and you will probably want to add many more specific to the situation you are troubleshooting.

- Has the individual or team been working within their "Comfortable Capabilities and/or Capacity" which is a sustainable pace, or have they been working near peak capacity which is attainable but not sustainable?

- What were the weather conditions?

- What are the project conditions with other trades? With the customer?

- What was the condition of the tools or equipment used to do the task?

Regularly run through this gauntlet of questions and they will soon become second nature.

- Observe your own behaviors and turn these questions on yourself. They are great for self-reflection.

- If someone starts asking you questions like this, make the assumption they are simply trying to troubleshoot. Take it as feedback and not criticism.

- If you are using these questions with someone else, focus on building up and not beating up. The best coaches give very frequent "GPS Feedback" to their team.