Lean Principle - Observation (Gemba Walks and Learning to See)

One of the most important tools for improving productivity is going to the jobsite or work area and observing for an extended period of time with the intent to understand but not to immediately interact. Observation progresses through about 7 stages.

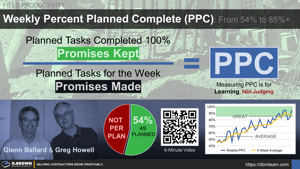

field productivity lean constructionWeekly Percent Planned Complete (PPC) and Project Performance

Improving the project planning and delivery process starts with improving predictability around the schedule. Nearly every Superintendent and Foreman is familiar with the Short-Interval-Plan (SIP) and typically fill one out weekly looking ahead 1+ weeks.

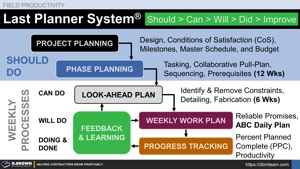

lean constructionLast Planner System (LPS) Overview: Should > Can > Will > Did > Improve

The Last Planner System (LPS) developed by the Lean Construction Institute (LCI) is the codification of the practices used by the best project teams. There are elements that EVERY contractor can use to improve performance of their projects and business.

lean constructionLean Principle - Kaizen (Every Detail Matters)

As contractors build their businesses, it is important to look at every detail from the first meeting with a potential customer through winning and building the project. This same attention to detail also applies to supporting operations and talent.

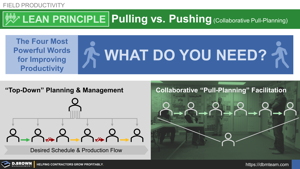

field productivity lean constructionLean Principle - Pulling vs. Pushing and the Four Most Powerful Words for Improving Productivity

“What do you need?” are the four most powerful words for improving productivity, developing a team, and building engagement. "Pull-Planning" can be used way beyond building a project. The principle is the foundation for many aspects of life and business.

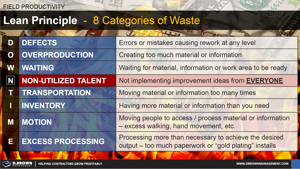

labor productivity lean construction project managementLean Principle - 8 Categories of Waste

The first step in improving labor productivity in construction is improving everyone’s ability to see the waste. Waste can then be broken down into 8 major categories. Like colors these are often interrelated.

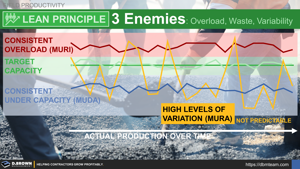

field productivity lean constructionLean Principle - 3 Enemies of Lean

Profitable growth comes from operating within a target capacity and capability range - and continually increasing those ranges. Operating with consistent overload, consistent under capacity, or with consistently high variability is not sustainable.

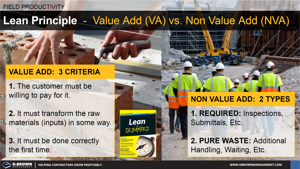

labor productivity lean constructionLean Principle - Value Add vs. Non Value Add

For specialty contractors the field workforce represents most of their competitive advantage as well as their biggest source of variability. Making improvements to field productivity requires deeply understanding what truly adds value to the customer.

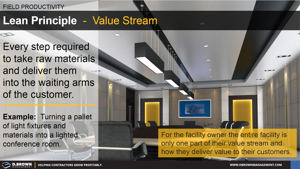

field productivity lean constructionLean Principle - Value Stream

A contractor’s value stream is every step required to take raw materials and information then deliver a completed project to the waiting hands of a customer. Deep understanding of this value stream is the foundation for major productivity improvements.

field productivity lean constructionLean Principle - Understanding Lean Construciton

Lean is a body of knowledge dating back hundreds of years focused on sustainably growing an organization. During the last 20 years the construction industry has been rapidly adopting some of these tools to improve productivity.

field productivity lean construction