At the heart of the lean body of knowledge is a care for people and sustainability.

For a contractor to grow sustainably through each stage growth, they must have made the right strategic market choices and developed a business model with performance standards including methods and outcomes that supports those strategies.

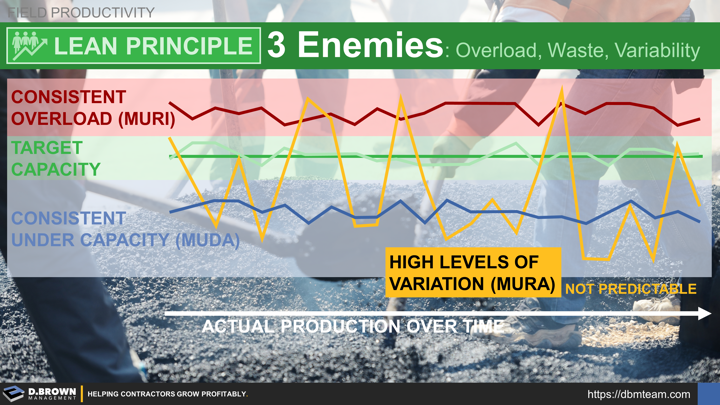

OVERLOAD - Consistently Operating Above Target Capacity

Pushing equipment, subcontractors, vendors, and especially people too far beyond their capacity to the point of unproductive stress. In equipment terms, this would be pushing the equipment beyond its specifications leading to increased wear and tear or not taking it in for routine preventive maintenance, both of which increase operating costs and the much more costly incidents of unplanned downtime.

Consistent stress from the team leads to lower morale and turnover which is even more costly with the continuing talent shortage. Consistent overload can be one of the early signs that you are at a growth inflection point as a company or in your career and looking at the challenges faced today through the lens of yesterday's knowledge, processes, and tools. It could also mean a mismatch between the job role and person. The root of this could be a poorly defined job role which is common with growth, a management problem, a training issue, or a mismatch of aptitude with each being handled differently.

In any case, overload is only sometimes profitable in the short-term and is never sustainable. If one person on your team is complaining of stress, it may be them. If multiple people are, it may be time to look at different solutions.

WASTE - Consistently Operating Below Capacity

This will typically show up as a lack of profitability overall for the company and lack of productivity on projects. It is another sign that you are potentially at a growth inflection point. The easy finger to point is at "laziness" but the truth is that very few people wake up in the morning with the goal of doing a bad job.

As an example, most problems with field productivity have nothing to do with the speed that individual crafts people are working. There is a big variation between your fasted 25% and your slowest 25% but the far bigger gaps in productivity come down to great support functions and leadership at the Foreman level ensuring that Time-on-Tools (ToT) is maximized by ensuring the six pillars of productivity are in place for every task before starting.

The other area to look at is ensuring that your systems are in alignment with your stage of growth, and that unnecessary stifling bureaucracy hasn't crept into your processes over time. Having too much management including too many signoffs and quality control (QC) points can be just as damaging as too few. Your systems, structure, and strategies must all be appropriate for your stage of growth. What works at 50-person contractor won't work at 500. Reading a great management book (or listening to a consultant) about a great system for a 1,500-person contractor isn't likely appropriate for a 150-person contractor.

VARIABILITY - Consistently Unpredictable

It is impossible to eliminate all variability - that is why standards must include a target, and a tolerance range with clear escalation paths when performance happens beyond those ranges. There is an increasing cost to tighter and tighter tolerance ranges which must be balanced with the return for those tighter ranges to find the optimum range. This is what your business model must be built around.

Those standards and the business model must evolve with growth, types of projects, and the available workforce.

You can't build a sustainably profitable business around high variability. It is one of the indicators that you may be at a growth inflection point.

This is also an area where you must measure and watch trends over time. Our minds are horrible when it comes to seeing variability for what it is. Just a few of the cognitive biases that get in our way:

- Recency Bias

- Availability Heuristic

- Confirmation Bias

- Survivorship Bias

- Optimism Bias - Focusing on High Points

- Pessimism - The Opposite - Focusing on Low Points

Always do the math. Always build your own models. Embrace others on your team who do the same. Remember to balance the dichotomy:

"The days of the intuitive manager are numbered." - Peter F. Drucker

"Not everything that counts can be counted and not everything that can be counted counts." - William Bruce Cameran