The human mind is amazing at pattern recognition - that is how our brains process the world. Consider simple categories of threat vs. non-threat that keeps us alive. Diving deeper into categories of food - bitter (many poisons) or sweet (yummy + quick energy). Colors - there are millions of them and they start with high levels of primary colors and get subsequently broken down into more detail.

This level of categorization helps keep us alive and allows us to communicate with each other. We can all look at a stop sign and say “red” where a computer would communicate ‘#e70707” as the specific color.

We know that our role is to create the “Perfect Day” and we do that by looking at every step in the process identifying only those that add value and looking at the 3 major enemies of a lean operation.

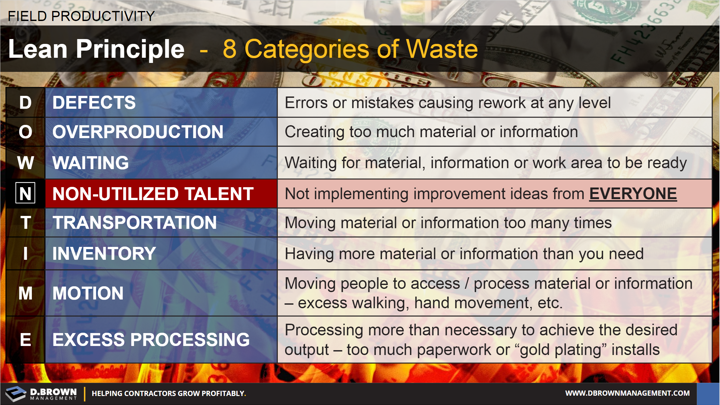

Waste can then be broken down into 8 major categories. Like colors these are often interrelated. Look at your day and see if you can identify any of these:

- Defects

- Overproduction

- Waiting

- Non-Utilized Talent

- Transportation

- Inventory

- Motion

- Excess Processing

The acronym ‘DOWNTIME’ will help you remember.

Quiz others on your team. Turn it into a game. This is where productivity improvements start.