This statement is only funny because it is so true. It is one of the first mindsets you have to break within yourself and then within your team if you want to achieve consistent operational excellence.

New technologies, project types, and project delivery methods combined with a growing organization mean that processes will always be changing and there will always be problems to solve.

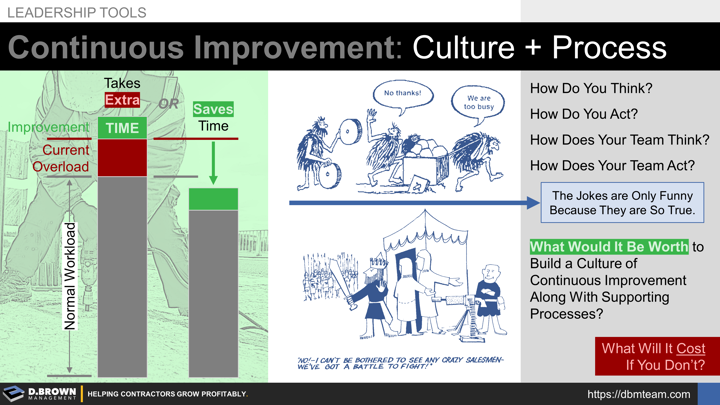

When people have the mindset that time spent improving a process (PDCA - Plan > Do > Check > Act) or learning is “Extra Time” on top of their already overloaded schedules then they approach it with a negative attitude. They always find ways to prioritize daily work and emergencies over these improvement activities.

Leaders must break this cycle in themselves and their teams to truly unlock performance.

If you start a routine habit of working on improvements each day, do you believe:

- This will take extra time on top of the extra workload you are already handling?

- This extra time spent will create rapid returns and be saving you time within days?

We are in a talent shortage that will continue to decline through 2030 while the construction market is continuing to expand in most areas.

There are plenty of satirical jokes out there about people being too busy. These jokes range from people struggling to move a cart with square wheels to a King charging into battle with a sword because he is too busy to meet with a salesman selling a machine gun. Sadly, these jokes are only funny because there is an incredible element of truth in them.

As contractors grow, these problems continue to compound, as do the returns for even small improvements across hundreds of people. Think about how incremental improvements to field productivity and cash flow can add up quickly to dramatically improve your scoreboard.

How do you think and act when it comes to continuous improvements?

Are your actions and their results highly visible to your team? Remember that the spotlight of leadership is bright when it comes to problems but incredibly diffused when it comes to successes. Leading change is never easy.

How does your team think and act?

What would it be worth to build a culture of continuous improvement along with supporting processes? An example of a supporting process would be 5S in the fabrication shop each morning and perhaps something similar with Project Management files.

What will it cost you if you don't? Think about the turnover caused from continuous overload of team members. Think about those small things measured in minutes of waste but occurring dozens of times each day across the company. Those all add up.