Operational excellence must be a major component of every contractor’s strategy and baked into their daily behaviors.

The Return on Investment (ROI) for each of these levels of integration and optimization changes dramatically with headcount growth. What may be a competitive advantage at one stage of growth often becomes an undifferentiated prerequisite at the next stage of growth. You must constantly balance out avoiding premature optimization with losing your competitive advantage. This really comes down to the fourth and fifth strategic questions.

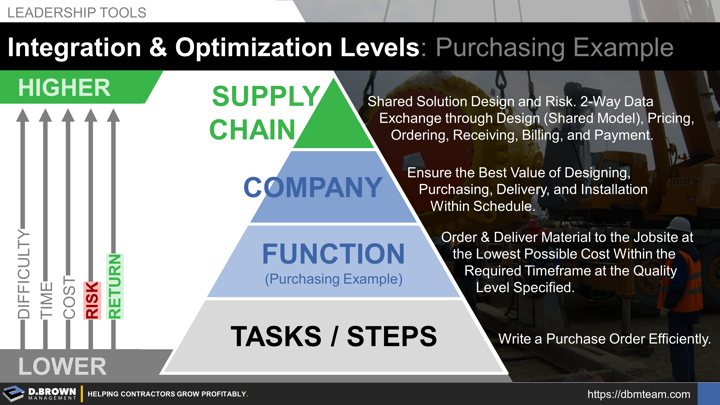

There are four major layers of integration and optimization. Each are related. Each layer is critical, creating momentum for other layers. Optimization at each layer requires different levels of thinking, different technology, and a longer time span.

- Task: Can be further broken down into discrete steps with every element of time and motion broken down to yield the most efficient output.

- Function: Optimization is about consistent and efficient execution by everyone within a functional area such as field, project management, purchasing, etc.

- Company: Most effective flow through across all functional areas of the company. For example - the most efficient material installation is that material that never had to be ordered or installed because it was value-engineered out during the design process.

- Supply Chain: Downstream integration to your suppliers and subcontractors. Integration with other contractors on the project if applicable, upstream to your customer and efficient communication with architects and consulting engineers.

Example - Purchasing

- Write a Purchase Order (PO) efficiently.

- Order & deliver material to the jobsite at the lowest possible cost within the required timeframe at the quality level specified.

- Ensure the best value of designing, purchasing, delivery, and installation within schedule.

- Shared solution design and risk. 2-Way data exchange through design (shared model), pricing, ordering, receiving, billing, and payment.