Seven Stages of Observation Effectiveness

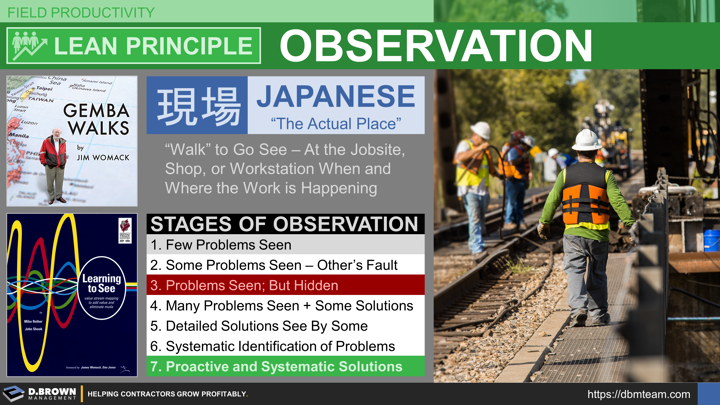

Gemba is a Japanese word roughly translating to "The Actual Place" with the concept being to always observe the work where and when it is happening. This may be the jobsite, meetings, someone's workstation, or your shop/yard.

From the smallest of operational improvements through major strategic choices, observation is the foundation. Individual and team capabilities for observation develop through about seven different stages:

- Few problems (or opportunities) are seen. This is where we all start in life and in our careers. Checklists can be a huge help for expanding the capability for people to see everything that is going on which is why they are an important part of the 5S Process.

- Some problems are seen more than before but most are seen as being someone else's fault. This is where daily processes like 5S and small "Kaizen" improvements help develop someone's internal locus of control. Managers can do a lot to help develop their people into being proactive about problems and opportunities.

- Problems are seen but hidden. Not everyone goes through this stage. If it is widespread within the organization, it is a cultural problem caused by behaviors from leadership. If it is isolated, it is likely from a person's prior experience as a child or from a past company where "Kill the Messenger" behavior was the norm.

- Nearly all the problems (or opportunities) are being seen. Some solutions are being identified but mostly at the conceptual level. At this point, it is likely a few individuals on the team that are operating at this level.

- Detailed solutions are seen by some. If there are enough of those people on the team and they also have strengths in implementing the solutions, then the contractor will continue growing profitably.

- Systematic identification of problems is being used to close the gap faster between those who see the full range of problems/opportunities and those who are learning to see. These supporting tools including checklists, reporting, and other visual indicators supported by training and coaching. This is where you start to make the transition from individual capabilities to organizational capabilities.

- Proactive and systematic solutions to the problems identified building on the prior stage moves a contractor into a scalable and sustainable construction business that is prepared for successions at all levels.

Work observations have a lot to do with asking good questions in a way that engages but doesn't interrupt the people doing the work.

Construction "Gemba Walk" Observation Example

Unified Works / Rich Seiler provides a good example of walking the job with the intent to learn.

Remember that work observations are not limited to the jobsite.

Work observations and improvements are just as important for bringing in good work and supporting field productivity. Look at all elements of your business model.

Additional Resources

- Gemba Walks

- Learning to See: Value Stream Mapping to Add Value and Eliminate MUDA

- Creating a Lean Culture: Tools to Sustain Lean Conversions