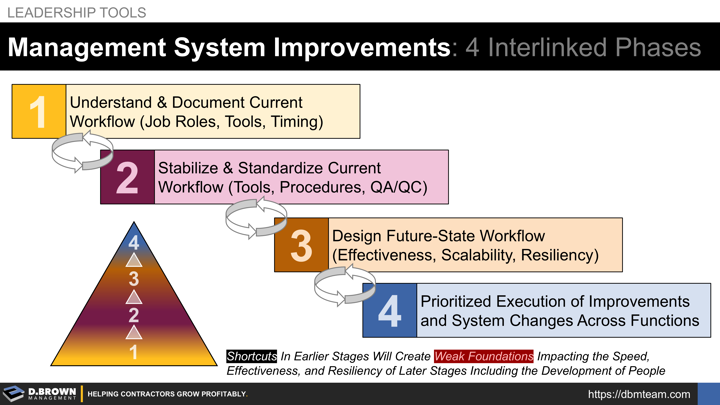

Management systems are the glue that connects a contactor's strategies, plans, projects, people, and resources together to make progress toward its vision. The right management systems create predictable outcomes based on the business model. As a note, we target 2-3X industry benchmarks for most outcome metrics, and this is achievable through a balanced approach. Management systems are the foundation for growth and must evolve as conditions change. That evolution is best managed in four distinct but interlinked phases:

- Understanding and documenting the current workflow, including job roles, external parties involved, tasks, and timing.

- Stabilizing and standardizing the current workflow—tools, standard procedures, quality assurance (QA - right process), and quality control (QC - right outcomes).

- Designing the future-state workflow may involve introducing new or different job roles and tools for effectiveness, resiliency, and scalability. All systems tend to break down at about 3X headcount growth or when market conditions and technology evolve, requiring continuous adaptation.

- Prioritized execution of improvements including roll-out, adoption, and ongoing management across all functions of the company.

Shortcuts in the early stages create weak foundations, ultimately reducing the speed, effectiveness, and resiliency of later stages—including the development of people.

A Team Approach

Working through these four phases will improve succession readiness at all levels and keep the team aligned. Identify the right team members for an improvement team through a combination of:

- Deep subject matter expertise in one or more of the areas impacted.

- Influence on others in the group—those trusted people that "glue" everyone and everything together through relationships.

- Capabilities and aptitudes for systems-level thinking and structured problem solving. See progressive levels of questions to help identify this and review the Time Span 101 (SST) videos.

Phase 1: Understand and Document Current Workflow

The is the equivalent of doing a survey of an existing building before designing a remodel. Any changes within a business are like having to do a seismic retrofit and MEP upgrade on a hospital that must remain in operation. The primary tool we use for this are a series of high-involvement workflow mapping sessions focused typically on a subset of the Project Value Stream (PVS) or Talent Value Stream (TVS) which cut across multiple functions and job roles in a contractor.

- Initial workflow map and list of tools with team of 5-8 people + a facilitator.

- 3-5 iterations of current workflow to get the details accurate (see Phase 2 below)

- Inventory of the tools used (software, reports, checklists, forms, worksheets, etc.).

- Inventory of any currently documented procedures and related training for the different tasks and tools.

- Inventory of company-specific acronyms or other vocabulary used which helps new people onboard more effectively.

- Evaluate consistency, depth, and breadth of "Tribal Knowledge" as 90% or more of procedural details will always be undocumented.

- Evaluate team's ability to collaborate with each other and have productive conversations (not arguments) including asking "Good Questions"

- Evaluate team's ability to document and explain a workflow including the desired outcomes of that workflow.

- Evaluate team's capabilities, capacity, desire, and aptitude levels across a variety of talent dimensions - this is the advantage of having an experienced but unbiased 3rd party facilitate.

Phase 2: Stabilize and Standardize Current Workflow (Tools, Procedures, Roles, Responsibilities, QA/QC, etc.)

The most valuable "innovation" for most contractors is simply the consistency of execution. This requires incredible levels of discipline for those in supervisory or management roles. This management of the details is not as interesting as looking for some "innovative" or "new" technology that will magically improve everything. As James Clear describes, you must "fall in love with the boredom" of routine to achieve mastery in sports, business, and life.

Phase 2 is easily the most critical phase. In many cases, there is no need to move to phases 3 and 4 because other bottlenecks and constraints in your business model will yield a higher return on time and capital invested.

Phase 2 starts with the first or second iteration of documenting the current workflow. While it may resemble Phases 3 and 4, the key difference is that all improvements are minor tweaks to the existing system—typically taking 2-4 hours each—and are implemented during the normal course of work.

- Organize all existing tools (physical tools, software, reports, forms, checklists, worksheets, etc.) into standard locations.

- Standardize existing tools within reason. For example, we often seen dozens of individual Short-Interval-Plan (SIP) formats, which can usually be simplified into 2-3 specific use cases that cover 95% of all projects.

- Streamline existing tools within reason (< 40 hours total). This may include standardizing software configurations, protecting Excel worksheets with locked cells, adding drop-down selections for standard information, creating validation checks for common errors, or automating data syncing. These simple changes improve usability.

- Observe work as it actually happens. Frequently, how people describe the work is different than how it is performed in practice.

- Develop and deliver training on existing tools to ensure consistent use. Often, checklists embedded into the tool or posted visibly in a work area are sufficient. Timely, actionable, and consistent management feedback is one of the best training tools.

- Involve a progressively wider team with each iteration of documenting the current workflow (Phase 1). This fosters alignment, evaluation, and training while standardizing processes.

- Identify minor improvements (< 40 hours total) in the process, such as eliminating a step, resequencing tasks, replacing meetings with alternative information-sharing methods, or shifting responsibilities while iterating through the workflow.

- Standardize acronyms and terminology used across the organization.

- Standardize operating rhythms for tasks, meetings, reports, and management processes where applicable.

- Standardize measurable outcomes and define the leading activities required to achieve them.

- Standardize management work to ensure both workflow consistency (Quality Assurance) and desired outcomes (Quality Control).

- Evaluate the team's ability to identify and implement improvements quickly.

- Evaluate the team's ability to execute consistently, particularly those in supervisory or management roles.

When a team executes consistently within a given system, the changes required in Phases 3 and 4 happen much faster and deliver a significantly higher return. We have seen contractors waste considerable time and money on "new" systems, only to see the same problems with execution resurface.

Phase 3: Designing the Future-State Workflow (Effectiveness, Scalability, Resiliency)

The first step in Phase 3 is clarifying the problem you are solving by designing a new workflow. However, do not move into Phase 3 until you have completed multiple standardization cycles in Phase 2. At that point, you can objectively assess:

- How effective the current system is when standardized. Often, the push for a new system is based on poor metrics or anecdotal feedback about an inconsistently executed existing system.

- The team's capabilities, capacity, aptitude, and desire for consistent execution. If the management team struggles to execute consistently with the current system, they will likely struggle just as much with any new system.

There are plenty of reasons why a change is required. Changes to the management systems, structure, workflows, and tools are often necessary as a contractor navigates different stages of growth. Most workflows do not survive two stages of growth effectively. Some common drivers for change include:

- A piece of equipment or software will no longer be available, and alternatives require redesign of the workflow.

- The current workflow (including key tools) has hit scalability limits, causing excessive errors, downtime, or slowdowns—issues that will only worsen over time.

- The current workflow isn't resilient because of too much dependence on certain individuals or tools.

- There is a materially better workflow and associated set of tools that will improve outcomes by 30% or more in terms of lowered costs or improved quality. An example of this would be the use of Scanning, BIM models, and Total Stations for layout.

When designing the future-state workflow, use the same skills learned in Phase 1. The primary difference is the inclusion of new stakeholders. For key workflows, it is incredibly valuable to bring in:

- Customers, vendors, subcontractors, and other external parties involved in the workflow. Often, the biggest constraints (and opportunities) are external. Collaborate on the high-level workflow with them, then refine internal details separately.

- Specialists in relevant equipment and technology. Keep in mind that sales engineers understand how a tool performs a task but may not see the entire workflow. This is where the structured approach from Phase 1 is critical.

- Industry peers who have navigated similar changes or operate at the level you are growing toward.

- Higher-level leadership who can provide insights across multiple business functions and long-term market trends. Workflow must support strategic decisions at all levels.

- Experienced, unbiased third-party facilitators can be invaluable for keeping everyone focused on the workflow and expected outcomes (design) rather than jumping toward decisions.

As with Phase 1, designing the future-state workflow will typically take 3-5 iterations.

Key reminders:

-

The first decision in Phase 3 is whether it is even necessary.

-

Strong execution in Phase 2 is a prerequisite for moving to Phase 3.

-

While Phase 4 may seem exciting and tangible, rushing into it without a well-integrated Phase 3 is like starting a project with disorganized construction documents—invest the right resources here.

Phase 4: Prioritized Execution of Improvements and System Changes Across Functions

Phase 4 is where execution becomes highly detailed, beginning with a structured plan that includes selection, integration, initial rollout, The best starting point is this video on prioritization—misaligned teams focused on "moving fast" oven achieve results the slowest. Proper alignment ensures efficiency and effectiveness in execution.

Please contact us to discuss these four phases and how they apply to your vision, business, team, and process improvement objectives. We will freely share insights, including workflow mapping models, role definitions, meeting agendas, and key questions to consider—anything that can help you improve.