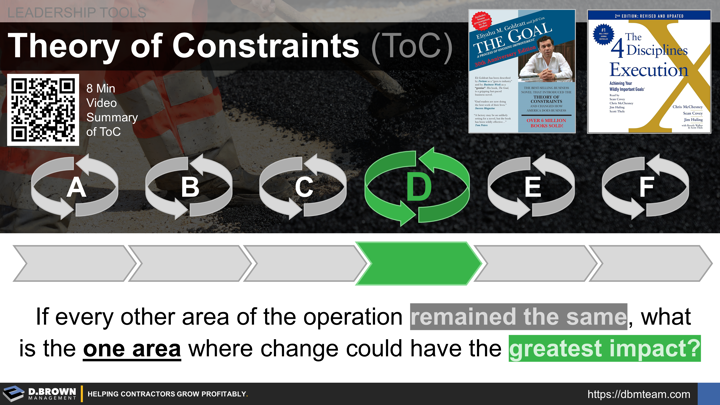

This great question was framed by Chris McChesney in The 4 Disciplines of Execution (4DX), first published in 2012 and updated in 2021. Though not referenced in the book, this principle of focusing on the constraint to the business was introduced in 1984 as the Theory of Constraints (ToC) by Dr. Eliyahu M. Goldratt in a book titled "The Goal." All bodies of knowledge around improvements are tied together in some way - ToC is often used alongside Six Sigma and lean. While it started with a focus in manufacturing, you can see elements in takt planning which is gaining traction in construction just like lean.

Identify and Eliminate Bottlenecks: A bottleneck refers to any stage in a process that has a lower capacity than preceding or subsequent stages, causing a slowdown in the overall process. It is a point where the flow of work is impeded, leading to delays and reduced throughput. In manufacturing, for example, if one machine operates slower than the rest, it creates a backlog of work, making it a bottleneck.

Focus on Constraints First: A constraint, in the context of ToC, is a broader term that refers to anything that limits a system from achieving higher performance relative to its goal. Constraints can be physical, like a machine with limited capacity (similar to a bottleneck), or non-physical, such as a company policy, market demand, or even a mindset. In ToC, the focus is on identifying and managing the system's primary constraint as this is key to achieving significant improvements in performance.

In summary, while all constraints can cause bottlenecks, not all bottlenecks are constraints in the strategic sense used in ToC. The primary constraint is the one factor that is most limiting the system from achieving higher performance relative to its goal.

We recommend watching the short videos above (11 minutes total) with a notepad in hand after getting a simple visual on all aspects of your business model. This simple illustration of a Contractor Business Model may be a helpful starting point.

- What bottlenecks do you have within your Project Value Stream (PVS)?

- What bottlenecks do you have within your Critical Supporting Operations (CSO)?

- What bottlenecks do you have within your Talent Value Stream (TVS)?

- What bottlenecks do you have externally in the market?

- Are there conditions you see in the future that would dramatically change your answers including key people retiring or shifts in the market?

- Looking at your answers above, what is your constraint?

Talking through these questions with an experienced but unbiased 3rd party can be invaluable. Resources are finite. Which bottlenecks you choose to eliminate, to what degree, and in what sequence will have a dramatic impact on your outcomes.

As you do the math of prioritization and choose which bottleneck(s) to focus on, consider what quantification of winning would look like. What outcomes do you expect? Then consider what the leading activities and indicators would look like to help your team get there faster.

All relationships begin with a simple conversation.