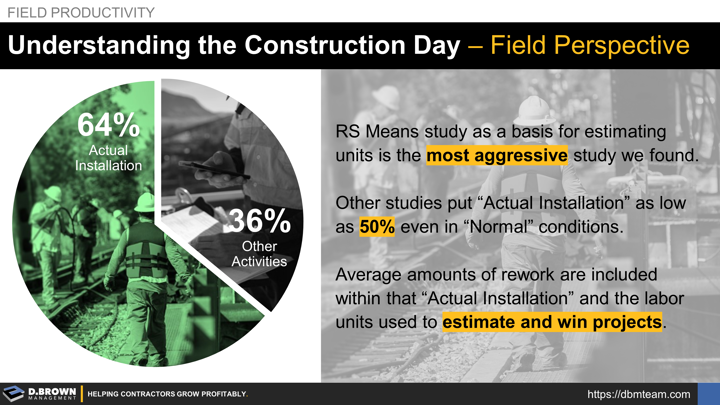

Depending on the trade, project, and the labor, study the time spent on actual installation ranges from 50-64%.

Remaining time is spent on non-installation activities including material logistics, movement around the jobsite, breaks, layout, mobilization to the work area, etc.

These labor studies include craft labor and direct supervision at the foreman level.

An average amount of rework and typical jobsite conditions are all factored into these studies.

These form the basis for the labor units all contractors use to estimate projects.

Assuming our quantity take-offs are accurate, this is why multiple contractors can be so incredibly close in a competitive bidding situation.

Projects are then budgeted with these labor units and we manage projects to meet these budgets.

BOTTOM LINE

There is a significant amount of non-installation time built into the labor units the whole industry uses. Just increasing the actual installation time by a few minutes will make a contractor significantly more competitive and profitable.