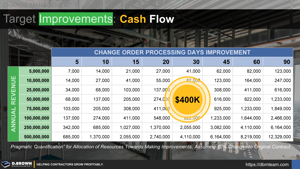

Changes and Cash Flow Improvement

Construction is a cash-intensive business and change orders are often one of the root causes of poor cash flow. A 30-day improvement to change management workflow can generate over $400K in additional cash flow for a $50M contractor.

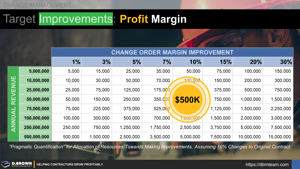

cash flow change management financial management foreman training project managementChange Order Profit Improvement

A 10% improvement in change order pricing for a $50M per year contractor will add $500K to their bottom line. This is not about simply marking up the change more, but rather, including the many costs that are typically missed or undervalued.

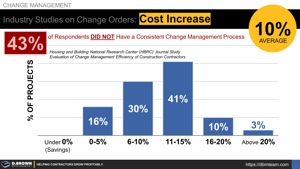

change management financial management foreman training project managementChange Orders and Average Cost Impact to the Project (Industry Survey)

Changes are a part of the construction process with many underlying causes. While we have all heard the average of 10% changes on construction projects, it is interesting to look at an industry study for validation.

change management foreman training project managementA Broader Definition of a Change on a Construction Project

The first step for contractors improving their management of changes on a project is simply earlier identification. This starts with a better definition of what a change really is, and then setting standards within your company around that definition.

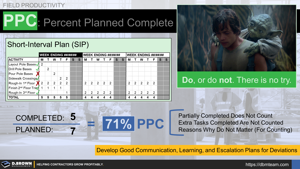

change management foreman training project managementPercent Planned Complete (PPC) - Calculation Example

Yoda would be the perfect coach for managing schedules on projects: “Do or do not. There is no try.” This is the heart of Percent Planned Complete (PPC) and the weekly cycle of continuous production improvement.

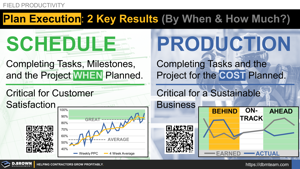

field productivity foreman training lean constructionTwo Key Results for Project Planning

There are two critical key results that should be focused on as part of every project planning process.

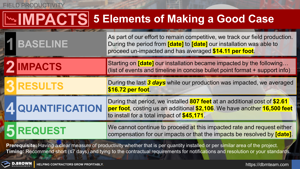

budget management change management foreman training labor productivity project management project planning schedule managementImpacted Productivity - Five Elements of Making a Good Case

Contractors are continually faced with costly impacts to their labor productivity and schedule with many beyond their direct control. The best Project Managers know how to identify, communicate, and mitigate these impacts.

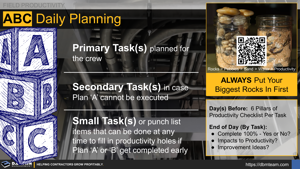

business management change management foreman training labor productivity negotiating project managementABC Daily Planning

Effective planning processes are the foundation for great production. The planning process can be seen as a series of tighter and tighter concentric circles with the bullseye being the daily plan. Daily feedback improves performance and mitigates risk.

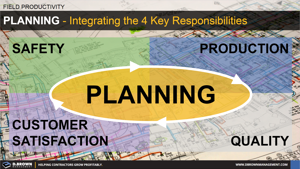

change management foreman training labor productivityPlanning - Integrating the 4 Key Responsibilities

Effective planning combined with regular feedback (at least weekly) combined with a structured look at how to improve each week is the key to integrating the four key responsibilities of a Foreman.

foreman training labor productivity project planningCreating The "Perfect Field Day"

Contractors build things and that comes down to the men and women in the field. They are the ones adding the value to the raw materials and that is ultimately what the customer is paying for.

foreman training labor productivity