The planning process can be seen as a series of tighter and tighter concentric circles with the bullseye being the daily plan. When the feedback and learning cycles are tightened to a daily habit, productivity improvements accelerate.

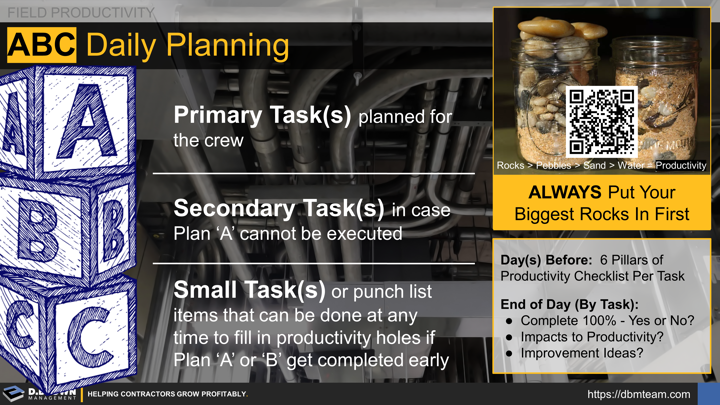

Think about productivity the same as filling a jar with rocks, gravel, and sand. You have to put your big rocks in first. By doing that, you can pack in a lot more gravel and sand. Each work day is your “jar” and your tasks are your rocks. Consider them this way:

- The biggest and most critical tasks to get accomplished.

- Larger backup tasks that can be completed in case something happens with your ‘A’ tasks. No matter how perfect your planning and preparation might be, there are always things that can go wrong. The faster your crew can swing over to Plan B, the less impact you will have to productivity.

- The work day rarely aligns perfectly with completion of your major tasks. C-level items are like the gravel and the sand in the jar. They are small punch-as-you-go items, pre-assembly or layout tasks that can be used to fill in those 15-60 minute production holes that often get filled with busy work.

Notes for Success

- All ABC tasks must meet all four critical elements of an effective task.

- The 'A' tasks will be on your Short-Interval Plan (SIP)

- All tasks must have all six pillars of productivity prepared for effectiveness. Depending on the project, you may be able to leverage a Field Engineer, Site Logistics Manager, or crew leader in training to help with these. As a Foreman, some or all of the responsibility can be delegated but the accountability remains with the Foreman.

- At the end of each day, identify what got completed, what was impacted and why, and how to improve the next day.

- Depending on what was impacted and to what degree, ensure that you escalate, communicate, and coordinate appropriately. This may include tracking time and cost impact and escalating to the Superintendent or Project Manager. It may include just noting the impacts in your daily log.

Test out the ABC Daily Planning process for a few months reflecting and refining at the end of each day. Remember that as you reflect back for day and week, looking at what got done according to plan and what didn't, including finishing early:

- The "Sweet Spot" for performance is about 75-90% to-plan (Percent Planned Complete - PPC)

- Above 90% consistently probably means you are (1) perfect, or (2) being too conservative on goal setting which impacts productivity.

- Below 75% consistently indicates problems to be worked through which could be (1) being far too aggressive on goal setting or (2) external factors including excessive changes having a big impact on the project which needs to be escalated.