Once you define what needs to be delivered (your scope, contract, specs, and plans) in order to maximize labor productivity, it then needs to be broken down into tasks that can be effectively managed.

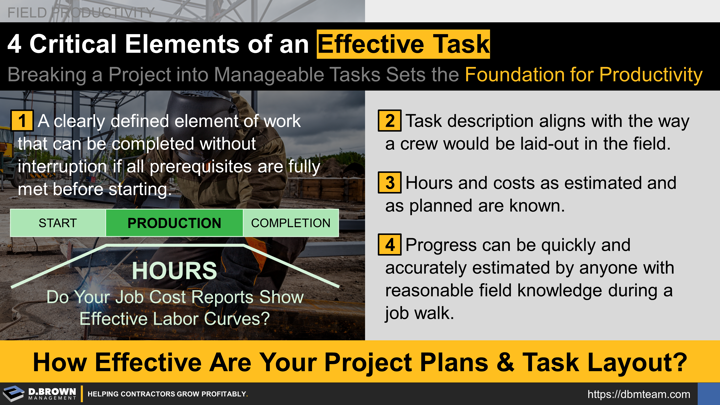

We look at four criteria when it comes to defining what an “Effective Task” looks like:

- It is a clearly defined element of work that can be started and completed WITHOUT interruption if all prerequisites are met before starting.

- The task description makes sense to anyone with basic trade knowledge aligning with how crews would actually be laid out in the field. When laying out a journey-level craftsperson in the field, the task would not reasonably be broken into smaller tasks.

- Hours and costs to complete the task as estimated and as planned are known, including what is remaining for field layout and installation after design in virtual construction and fabrication if applicable.

- ANYONE with reasonable trade knowledge would be able to QUICKLY assess the quantifiable status of the task during a job walk in terms of percent complete or estimated hours remaining to complete.

Do your job cost reports show effective labor curves? Smooth ramp-up to full production then ramp-down is the most desirable at the task, phase, scope, and project levels. The degree to which this can be achieved has a direct impact on safety, quality, and productivity.

While breaking the the project down into these tasks, the team must rigorously discuss the most effective sequencing, what could be prefabricated or kitted, what is required to be ready before the project starts, and all the other six pillars of task productivity.

Tasking at the beginning of the project ties into Short-Interval-Scheduling (SIP), tracking those via Percent Planned Complete (PPC), and using them daily with ABC Daily Planning.

Learn more in our Labor Productivity Workshop, including how it can be tailored for your company.

All relationships begin with a simple conversation - let's schedule time to talk about how we have helped contractors set up effective "Award-to-Start" systems and develop Foreman Training/Coaching programs.