While the process of continuous and relentless forced differentiation may seem harsh it is actually one of the kindest things you can do for everyone on the team.

- Break your field team into reasonably sized groups that you can compare within. For example for an electrical contractor it might be groups of field supervisors, underground, branch, 1-line, etc.

- Rank each group in order of best-to-worst looking at it from the angle of which order would you lay them off in during a downturn. Just the discussion of this with your top few managers will yield great conversations you can use to develop people.

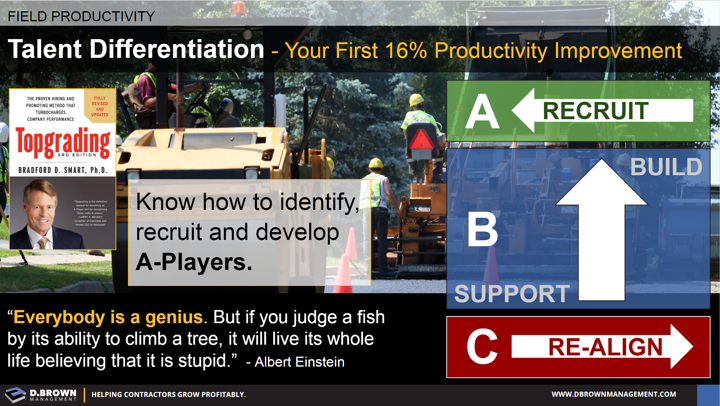

- Analyze the top 15% (A-Players) in each group looking for why they love working here, where they came from, how they built their careers and what their daily habits are. Use this information to refine your recruiting and training tactics.

- Look at the bottom 15% (C-Players) in each group and create an immediate plan to re-align them getting them into different positions within your company or helping them find a job with a company where they won’t be at the bottom. It is cruel to keep people in positions where they are failing. Always do this with respect and kindness.

- Focus on the middle (B-Players) developing training and systems around them to help them build some of the skills and habits of your A-Players.