Many articles have been written about the advantages of the Seller-Doer model for business development in the A/E/C industry. In this model, key managers are responsible for business development as well as managing the design and construction of the project. One of the primary reasons cited as a benefit of the Seller-Doer model is that clients prefer to work with those who are actually involved in the design or construction of a project rather than a pure business development professional.

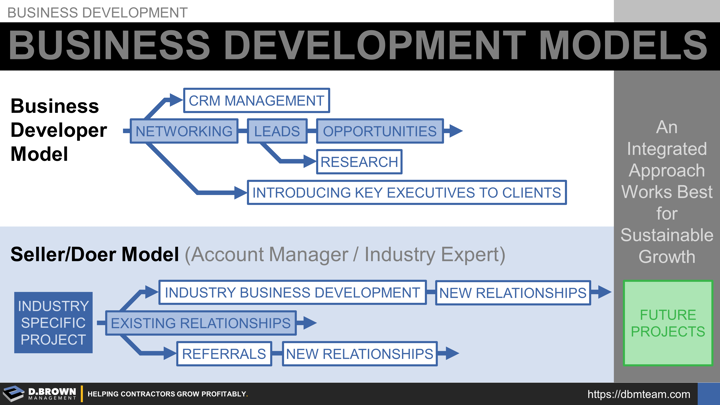

The following pages makes a strong case for General Contractors integrating the Seller-Doer model with dedicated Business Development Professionals for profitable growth. Download the full article.

Private Workshop: Determine what business development model is right for your team and market strategy.

Learn More About Raymond Braswell and Our General Contractor Solutions