Labor Units and Studies

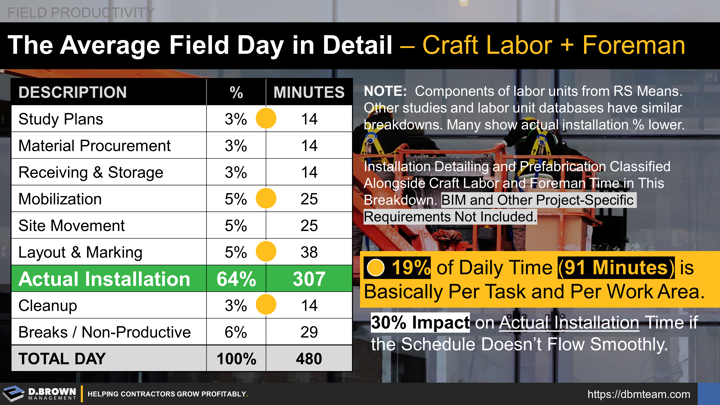

The chart above is taken from RS Means. Other studies and labor unit databases have similar breakdowns with many of them showing the "Actual Installation" time closer to 50% or even lower.

These studies are factored into the standard estimating database units that most contractors use as a basis for their bids, which is why multiple contractors can submit bids for a multi-million-dollar project and be within percentages of each other.

These usually include a composite crew up through the Foreman level.

Unless the project has a specific BIM requirement, things like detailing of the project or off-site fabrication (prefab / manufacturing) are not additive to these units. Those are all things that could be done on-site and would typically be done by the Foreman and crew.

Calculating Impacts

Since about 19% of the time each day (91 minutes) is basically per task and work area, any time that you have to move to "Plan B" or "Plan C" (ABC Daily Planning), you will still experience up to 30% or more total impact to your actual installation time. This is one of the many reasons why schedule flow is so critical.

Improving labor productivity comes down to three major levers:

- Improving the speed at which the crafts people actually do the work - how fast the wrenches are turned.

- Lowering the average cost per hour while maintaining productivity.

- Improving the ratio of time spent per day on installation versus non-installation activities. Time-on-Tools (ToT).

When you analyze your A-Players, you will see that they primarily attack 1 & 3 by studying every detail, setting themselves and their team up for success, training others, and improving with each cycle.

As a contractor navigates the stages of growth, their support systems and organizational structures for keeping the craft focused on installation becomes progressively more robust.

All the technologies we are seeing in the industry are great but without being put into the right workflows, most of those investments are not providing anywhere near the possible returns.

Talent shortages will continue to impact the industry. While we have the mechanisms to train new craftspeople relatively quickly, we are competing with a lot of other industries to attract that young talent. Compounding that problem, those with the depth of experience to effectively train those new craftspeople will continue to decline through 2030.