They focus on the smallest details of every movement looking at ways to eliminate waste while lowering the burden on the labor and increasing reliability.

There are 480 minutes in an 8 hour shift. During the typical construction day only 307 of those minutes are spent actually installing materials.

- Can you get people out to their work areas just 1 minute faster each day through motivation, planning and setting performance expectations?

- Could you get them installing their first production unit just 5 minutes faster each day by ensuring materials, tools and equipment were already in the work area?

- Could you keep them installing just 5 minutes longer at the end of the day using the same techniques?

- Could you reduce the number of times they stop work or are slowed down by not having the right information?

- What are the little tricks and techniques your best crafts person uses to shave just 30 seconds off of that unit installation that you repeat 20 times per day on average?

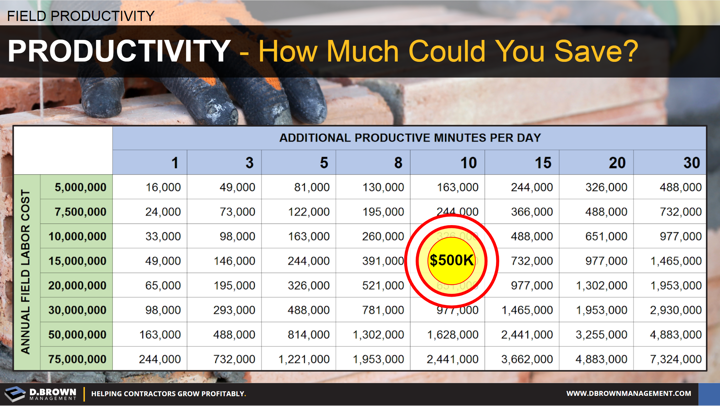

How much could you save if you got very deliberate with your training and execution over the next year?