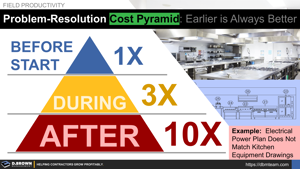

Problem-Resolution Cost Pyramid - Earlier is Always Better

An easy way to visualize the cost of problem resolution at different stages of construction is with this pyramid. The cost of the problem is the cost of the problem (1X). Finding it ahead of time minimizes the costs and maximizes customer satisfaction.

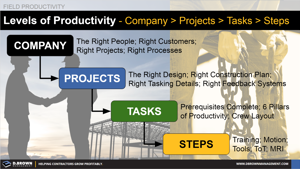

change management field productivity project managementLevels of Productivity

Making major improvements to labor productivity for contractors starts at the company level and must be rigorously managed all the way down to the individual steps in each task.

Lean Principle - Kaizen (Every Detail Matters)

As contractors build their businesses, it is important to look at every detail from the first meeting with a potential customer through winning and building the project. This same attention to detail also applies to supporting operations and talent.

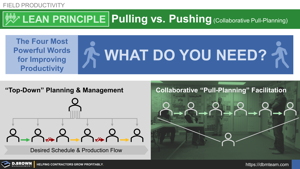

field productivity lean constructionLean Principle - Pulling vs. Pushing and the Four Most Powerful Words for Improving Productivity

“What do you need?” are the four most powerful words for improving productivity, developing a team, and building engagement. "Pull-Planning" can be used way beyond building a project. The principle is the foundation for many aspects of life and business.

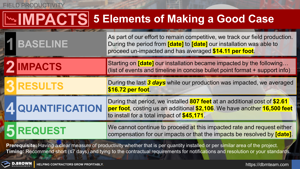

labor productivity lean construction project managementImpacted Productivity - Five Elements of Making a Good Case

Contractors are continually faced with costly impacts to their labor productivity and schedule with many beyond their direct control. The best Project Managers know how to identify, communicate, and mitigate these impacts.

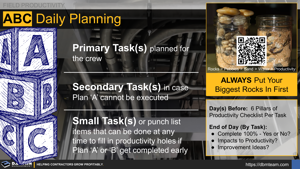

business management change management foreman training labor productivity negotiating project managementABC Daily Planning

Effective planning processes are the foundation for great production. The planning process can be seen as a series of tighter and tighter concentric circles with the bullseye being the daily plan. Daily feedback improves performance and mitigates risk.

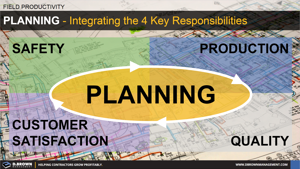

change management foreman training labor productivityPlanning - Integrating the 4 Key Responsibilities

Effective planning combined with regular feedback (at least weekly) combined with a structured look at how to improve each week is the key to integrating the four key responsibilities of a Foreman.

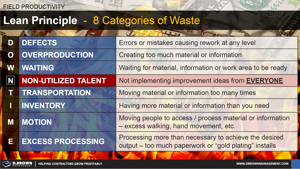

foreman training labor productivity project planningLean Principle - 8 Categories of Waste

The first step in improving labor productivity in construction is improving everyone’s ability to see the waste. Waste can then be broken down into 8 major categories. Like colors these are often interrelated.

field productivity lean constructionForeman - Four Sometimes Competing Responsibilities

No other position in the construction industry has a bigger impact on field productivity than the Foreman who is leading the crew on front-line. There are four major responsibilities the foreman has that often seem to be competing with each other:

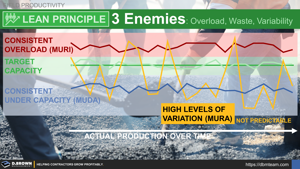

Lean Principle - 3 Enemies of Lean

Profitable growth comes from operating within a target capacity and capability range - and continually increasing those ranges. Operating with consistent overload, consistent under capacity, or with consistently high variability is not sustainable.

labor productivity lean construction