The capability to identify changes and conflicts early in the process is a combination of organizational structure, systems, management, training, and coaching.

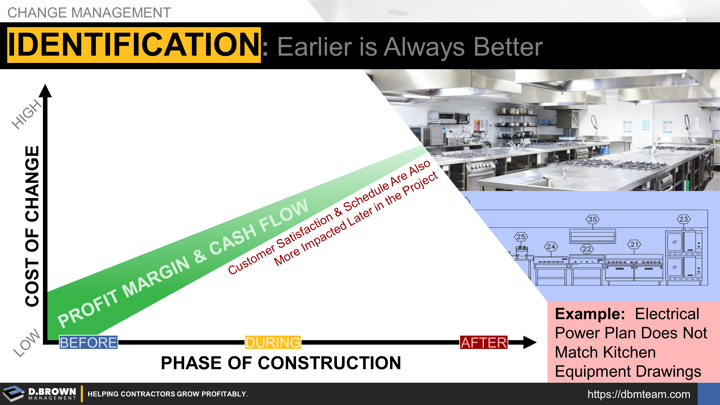

Keep in mind the problem-resolution cost pyramid for identification of changes as an example.

- The ability to identify and resolve potential issues from the very beginning of the design process will get your company involved in projects 6-18 months before anyone else even knows about them. This includes value-engineering options to help the project "pencil out" financially during the preconstruction process.

- Early identification will improve labor productivity dramatically.

- Identification is the first stage of the change management funnel.

- You can’t start your management processes until changes are identified and logged.

In general, the earlier you can identify changes and conflicts, the higher the customer satisfaction, profit margin, and cash flow with a faster schedule.

Which Project Manager in your company is best at early identification? Which Estimator? Field Supervisor?

What can you do to close the gaps between them and others on your team?

Change and conflict identification are trainable skills.

Scalability is not about what one person can do on your team but what the collective average performance capabilities are.