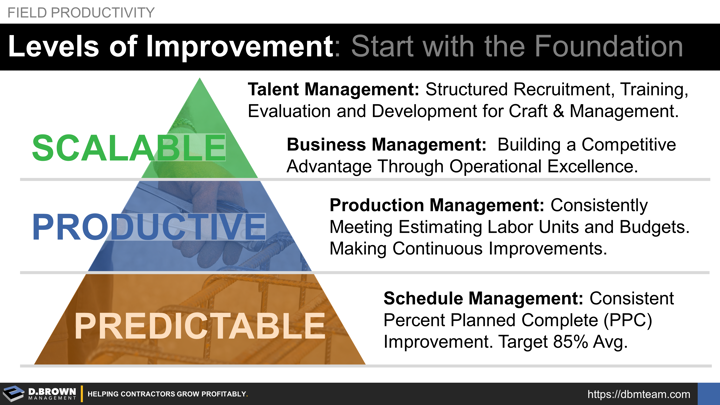

- PREDICTABLE - Ensuring that the outcome is consistent. For example, installing a piece of material is (1) done correctly the first time, each time and (2) that the time it takes for each unit is approximately the same each time - for example 1 hour each. There will be variability between the fastest 25% of crafts people you have and the slowest. That gap is wide but should be narrowing with good planning and support processes. Additionally, the variability for each craftsperson at a particular level will also be decreasing. Remember that variability impacts productivity and without standards there can be no true continuous improvement. Your ultimate objective at this stage is aligning your actual field installation with your estimating standards, and knowing the difference between your unit productivity and the average ones in the estimating databases many contractors rely upon.

- PRODUCTIVE - Continuously improving the cycle time getting it down to 50 minutes each. Then continuing to improve down to 45 minutes each; then 40. Being able to consistently perform at 70% of industry standard production rates gives you an unbeatable competitive advantage in all economic conditions. Remember that actual labor productivity is not the biggest problem with field productivity.

- SCALABLE - Developing the additional people to be able to replicate the productivity and developing the additional business based on that operational excellence that will use that additional talent. You won’t have a sustainable growth model if you don’t focus on both the talent and business development aggressively. You can’t focus on this until you have a predictable and productive system in place that truly adds value to the customer.

Field installation and everything required to support that is ultimately what contractors sell to their customers. As these levels of improvement relate to headcount and stages of growth - they approximately line up with stages 3, 4, and 5 respectively.

Progress will not be linear as with each stage of growth, the strategies, structure, and systems will also be evolving. These market choices will likely include larger and more complex projects, and possibly additional scopes of work. The management systems and standards must also continually evolve.