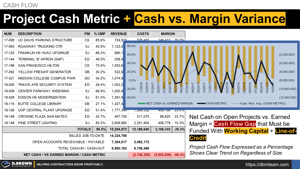

Project Cash Metric and Cash vs. Margin Variance

Contracting is a very capital-intensive business and it is critical to constantly be watching cash flow performance. This metric is the highest level of an “OUTCOME” for cash flow at the project level, summarizing the performance of ops and accounting.

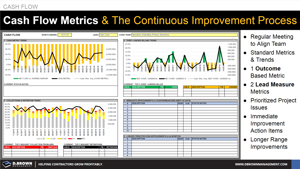

cash flow metricsCash Flow Metrics and The Continuous Improvement Process

Contractors can focus on 3 major metrics to continuously improve cash flow, truly making a “game” out of it.

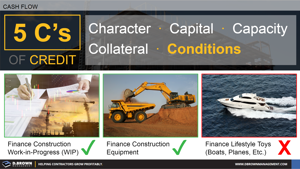

Cash Flow and the 5Cs of Credit - Conditions

The 5th of the 5Cs of Credit are the conditions for the loan, which is primarily what the funds will be used for. These conditions are here to protect the contractor as much as they are there to protect the bank.

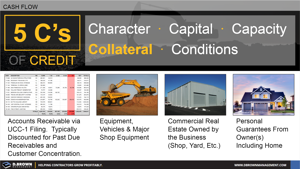

Cash Flow and the 5Cs of Credit - Collateral

The 4th of the 5Cs of Credit is how much and what type of collateral the contractor will put up as a guarantee. The collateral requirements change significantly as contractors grow.

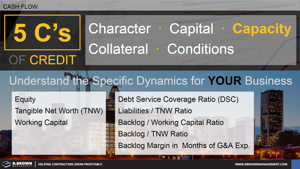

Cash Flow and the 5Cs of Credit - Capacity

The 3rd of the 5Cs of Credit is how much capacity your business has to profitably build the projects, ensuring payback of the loan or minimal risk in the case of insurance or bonding.

Cash Flow and the 5Cs of Credit - Capital

The 2nd of the 5Cs of Credit is how much capital you are putting at risk, along with your financial partner. Contractors should design and follow their own capital management policies appropriate for their business.

Cash Flow and the 5Cs of Credit - Character

Out of the 5C’s of Credit, character is the one that takes the longest to develop and can be lost in an instant. Character is like your safety EMR in that it is a multiplier for the other C’s, including how much capital you will need to leverage.

Cash Flow and the 5Cs of Credit - Overview

Contractors need strong financial partners, including banking, surety, and insurance to grow sustainably. It is important to understand how they evaluate your contracting business.

Cash Flow - 18 Tips to Improve Cash Flow Scoreboard

Construction contractors can use these 18 specific tips to improve their cash flow scoreboard.

Cash Flow Tip 18 - Making Cash Flow a Game

Imagine creating a culture where everyone ran into work with the same energy that fans and players run into a sporting event.