Project conditions are constantly changing. The role of the project team, primarily the Foreman and Project Manager is to:

- Have clarity on the outcomes expected, generally along these seven major objectives.

- Have Situational Awareness (SA) of the constantly changing project conditions.

- Communicate and confirm (ABC Communications), ensuring internal and external stakeholders are aligned.

- Make continual adjustments to execution (PDCA) to deliver consistent outcomes regardless of the inconsistencies from suppliers, customers, equipment, and team members. That is the magic of great management.

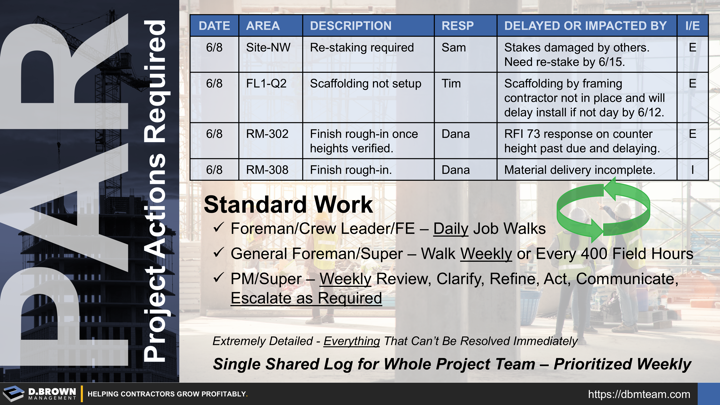

A Project Actions Required (PAR) list, kept in a shared location and updated daily, helps align other project management tools and processes, including:

- Project Planning (Schedule + Budget)

- Short-Interval-Planning (SIP)

- ABC Daily Planning

- Production Tracking

- RFIs

- Submittals

- Change Identification and Management

- Schedule of Values (SOV), Billings, Follow-Ups, and Cash Flow

Actions Required (ARs) was a term originated in the military in the 1940s to make a clear distinction between information and specific task directives. The intent, and sometimes the vocabulary, is used throughout project management and includes Action Items, Ball-in-Court, etc. Whatever you call it, the intent is clear:

- What specifically must be done?

- Who is directly responsible (DRI) for getting it done?

- When does this need to be done?

Situationally, you may include:

- Why does it need to be done? If it’s not obvious — or for training purposes — explaining the rationale and dependencies is a valuable practice.

- How does it need to be done? If applicable, this can include safety, quality, installation standards, code or contractual requirements, resources, budgets, operational boundaries, decision rights, etc. Along with explaining the rationale, explaining the how is a good practice for developing others.

Why PAR (Project Actions Required)? Par is a golf acronym that nearly everyone knows means the "target" for each hole. The term was originally used in 1870 and came from financial slang meaning "face value"— the standard or benchmark. On construction projects, using PAR as a disciplined daily and weekly workflow helps ensure the project meets targets across all key measures — including safety, quality, customer satisfaction, team development, productivity, profitability, and cash flow.

The Range of Project Actions Required (PAR)

- Some items may be automatically generated by a project management system — such as past-due RFIs, submittals, change proposals, back orders, or delayed material/equipment deliveries.

- Some may be large — such as a major change to the schedule or project team.

- Many will be incredibly small details — such as a missing label on an installation or a quick follow-up that will be done within hours to days.

Note that these items may be internal or external. While you can use a field in the tool to differentiate them, avoid treating them differently.

Why Write Them All Down?

- Everyone has cognitive limits for working memory and long-term memory. Those limits change over time and with conditions.

- Like safety, the best process is one that works comfortably within the limits of everyone on the team, leaving a margin of error. No one wants a safety harness rated for exactly our claimed body weight. :)

- Outside of the smallest service and special projects (SSP), multiple people with wide ranges of experience, capabilities, and capacity have to work together collaboratively as a team to deliver the project.

- Writing down your ARs helps refine your thinking, including how to best communicate - see the list above (what, who, when, why, and how).

- Notifications like “Past Due” or “Close-to-Due” that may come automatically from project management logs (RFIs, Submittals, Changes, Purchase Orders) or from job costing (cost vs. budget, accounts receivable) still need ARs to get them back on course. Not all notifications are of equal importance. Not all system notifications will be resolved the same way. Most people simply ignore the onslaught of notifications that come out of various PM systems. The notification is information — it is a nudge that an action may be required, but it is not the action.

- Seeing all the ARs from across the project laid out in one place allows you to use your brainpower for prioritization and communication rather than trying to hold all the details internally.

- Seemingly disconnected ARs and notes can paint a different picture when seen all together. Are there patterns in delays, schedule changes, rework, broken tools, missed material deliveries, etc.? Has scope creep unintentionally worked its way into the project through one too many favors or a misunderstood demarcation point?

- Reviewing the schedule, plans, specs, construction documents, and walking the job together to develop Project Actions Required (PAR) is a great tool for evaluating and developing new Crew Leaders, Foremen, Field Engineers, Project Engineers, and Project Managers. It makes Situational Awareness, problem solving, and prioritizing as visible as physical performance in a game.

- Having a disciplined process of developing and reviewing the ARs will narrow the gap between a less experienced and a more experienced project team, which is necessary given the shortage of talent in the construction industry.

- A log of ARs is an incredibly powerful project documentation tool — especially when tied together with images, video, and related project documentation.

Besides those, there are few benefits to having a shared Project Actions Required (PAR) list. :)

What's a No-No?

- Duplication of an existing system notification or process with no additional value-add. For example, some contractors have a robust cash flow process that includes its own form of cascading communications, responsibilities, and actions. Duplication of this in a PAR list would be 100% waste. If there are gaps in that system, improve that system, do not duplicate.

- Logging an AR after it is complete, or one that would be done anyway. There is a psychological benefit (dopamine hit) that comes from putting something on a list and crossing it off. That is a good thing if it is used to drive the project forward. If it is being done just for the feeling of crossing it off, that's like eating sugar — immediate rush but negative long-term benefits.

What's a Good Process?

- The Foreman walks their job mid-day, between the startup huddle and end-of-shift roll-up, making continuous notes of everything they see and need to take action on. For some project teams, this may include the Crew Leader and/or Field Engineer.

- The Project Manager and team — including the Project Engineer, Assistant Project Manager, Project Detailer, etc. — are all updating ARs as they go about their daily work.

- At the end of the day, possibly right after the shift ends, the Foreman and Project Manager have a quick sync-up call, going through the ARs, daily production, and lookahead over the next few days. What got completed? What was impacted? What’s on track? What’s delayed? What’s planned? What’s needed?

- The Superintendent walks the project with the Foreman at least every 400 field labor hours. This is a detailed review that serves as both an evaluation and coaching tool (see above). It’s also great risk mitigation for the project. Depending on the project team, this may be a General Foreman.

- Each week, the Project Manager clarifies the items, updates status, prioritizes, syncs with the internal project team, communicates with the customer and other external stakeholders, and escalates the items required.

Integrating these five elements into standard work by job role will accelerate team performance simply by synchronizing the timing. See the example standard work template for field leaders, which you can modify.

What's a Good Tool?

There are many great tools for this. The best tool is the one people will actually use — and use collaboratively. A project team of five people using five separate PAR lists is not effective. Managing five project teams, each using different tools, is also ineffective.

- We’ve seen some teams make great use of tools integrated with their project management software — including photos and other file attachments.

- We’ve also seen equally effective teams use a combination of notepads for in-the-moment tracking and a shared spreadsheet.

We would recommend starting with simple tools and improving only after you have 90% consistent use.

What are Typical Challenges?

- When the managers who directly oversee PMs and Foremen aren’t disciplined about executing the system, it breaks down. If the leader isn’t engaged, the process won’t work. This approach requires effective delegation — including clear standards and a QA/QC process. It’s not just an idea to float out to the project teams.

- Overcomplicating the system too early is a common pitfall. If it doesn’t work with a shared online spreadsheet (Microsoft, Google, Smartsheet, etc.) and a well-crafted weekly email to the customer, no amount of tech, apps, or AI will fix it.

Remember that this is just one tool that helps tactically integrate a variety of other processes. This only builds on the foundation created by pursuing the right opportunities, an accurate estimate, and a good initial project plan.