Labor Productivity

Field labor is the often the biggest variable on a construction project - making it the biggest risk and opportunity.

Field Productivity - The Improvement Pyramid

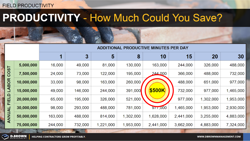

An improvement of a few minutes per day to actual installation time compounded monthly is worth about $800K per year for a $25M contractor. What is it worth to you? Improvements to field productivity can be viewed as 4 major stages of a pyramid.

labor productivitySimple Math of Labor Savings

What would it be worth for your company to improve your field productivity? There is an incredible amount of low-hanging fruit to be picked when it comes to improving labor productivity.

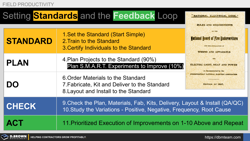

labor productivitySetting Standards and the Feedback Loop

Set the standard. Train to the standard. Certify to the standard. Plan the work to the standard. Execute to the plan and the standard. Check against the standard. Make prioritized improvements to the standard, training, planning, and execution.

field productivity lean construction sustainable growthLabor Productivity - How Much Could You Save?

Winners of the construction labor productivity is a game focus on minutes and seconds looking at ways to eliminate waste. There are 480 minutes in an 8 hour shift. Typically only 307 of them are spent installing material. What are 10 minutes worth?

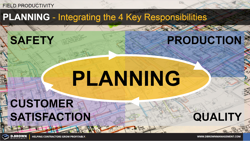

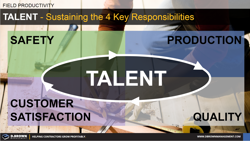

Foreman - Four Sometimes Competing Responsibilities

No other position in the construction industry has a bigger impact on field productivity than the Foreman who is leading the crew on front-line. There are four major responsibilities the foreman has that often seem to be competing with each other:

Planning - Integrating the 4 Key Responsibilities

Effective planning combined with regular feedback (at least weekly) combined with a structured look at how to improve each week is the key to integrating the four key responsibilities of a Foreman.

foreman training labor productivity project planningCreating The "Perfect Field Day"

Contractors build things and that comes down to the men and women in the field. They are the ones adding the value to the raw materials and that is ultimately what the customer is paying for.

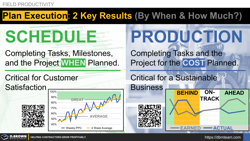

foreman training labor productivityTwo Key Results for Project Planning

There are two critical key results that should be focused on as part of every project planning process.

budget management change management foreman training labor productivity project management project planning schedule managementBe Specific About Problems

The business of construction is filled with constant problems. It’s not that great contractors don’t have problems, it's that great contractors have learned how to troubleshoot first, which allows them to learn from their problems faster.

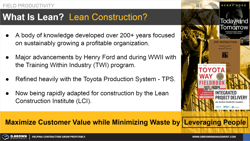

principles problem solving wisdomLean Principle - Understanding Lean Construciton

Lean is a body of knowledge dating back hundreds of years focused on sustainably growing an organization. During the last 20 years the construction industry has been rapidly adopting some of these tools to improve productivity.

field productivity lean constructionLean Principle - Value Stream

A contractor’s value stream is every step required to take raw materials and information then deliver a completed project to the waiting hands of a customer. Deep understanding of this value stream is the foundation for major productivity improvements.

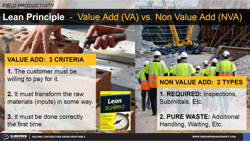

field productivity lean constructionLean Principle - Value Add vs. Non Value Add

For specialty contractors the field workforce represents most of their competitive advantage as well as their biggest source of variability. Making improvements to field productivity requires deeply understanding what truly adds value to the customer.

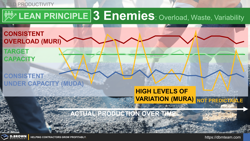

field productivity lean constructionLean Principle - 3 Enemies of Lean

Profitable growth comes from operating within a target capacity and capability range - and continually increasing those ranges. Operating with consistent overload, consistent under capacity, or with consistently high variability is not sustainable.

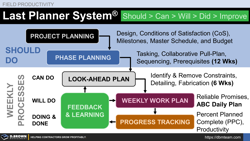

labor productivity lean constructionLast Planner System (LPS) Overview: Should > Can > Will > Did > Improve

The Last Planner System (LPS) developed by the Lean Construction Institute (LCI) is the codification of the practices used by the best project teams. There are elements that EVERY contractor can use to improve performance of their projects and business.

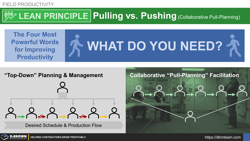

lean constructionLean Principle - Pulling vs. Pushing and the Four Most Powerful Words for Improving Productivity

“What do you need?” are the four most powerful words for improving productivity, developing a team, and building engagement. "Pull-Planning" can be used way beyond building a project. The principle is the foundation for many aspects of life and business.

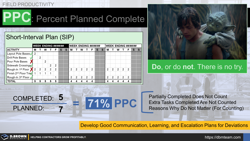

labor productivity lean construction project managementWeekly Percent Planned Complete (PPC) and Project Performance

Improving the project planning and delivery process starts with improving predictability around the schedule. Nearly every Superintendent and Foreman is familiar with the Short-Interval-Plan (SIP) and typically fill one out weekly looking ahead 1+ weeks.

lean constructionPercent Planned Complete (PPC) - Calculation Example

Yoda would be the perfect coach for managing schedules on projects: “Do or do not. There is no try.” This is the heart of Percent Planned Complete (PPC) and the weekly cycle of continuous production improvement.

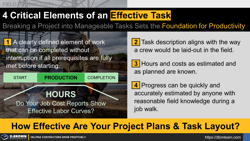

field productivity foreman training lean constructionFour Critical Elements of an Effective Task

Maximizing labor productivity starts with defining exactly what needs to be delivered and then breaking it down into tasks that can be effectively managed.

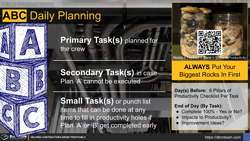

change management foreman training labor productivity project management project planning schedule managementABC Daily Planning

Effective planning processes are the foundation for great production. The planning process can be seen as a series of tighter and tighter concentric circles with the bullseye being the daily plan. Daily feedback improves performance and mitigates risk.

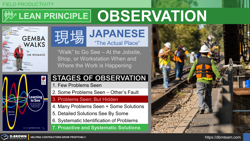

change management foreman training labor productivityLean Principle - Observation (Gemba Walks and Learning to See)

One of the most important tools for improving productivity is going to the jobsite or work area and observing for an extended period of time with the intent to understand but not to immediately interact. Observation progresses through about 7 stages.

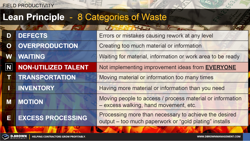

field productivity lean constructionLean Principle - 8 Categories of Waste

The first step in improving labor productivity in construction is improving everyone’s ability to see the waste. Waste can then be broken down into 8 major categories. Like colors these are often interrelated.

field productivity lean constructionLean Principle - Kaizen (Every Detail Matters)

As contractors build their businesses, it is important to look at every detail from the first meeting with a potential customer through winning and building the project. This same attention to detail also applies to supporting operations and talent.

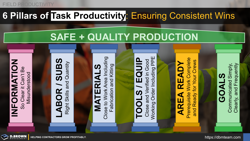

field productivity lean constructionThe Six Pillars of Task Productivity in the Field

Contractors can guarantee labor productivity on their projects by leading their project teams to focus relentlessly on ensuring that these 6 Pillars of Productivity are supporting each task on the job site.

field productivity foreman trainingClear Installation Information

For a contractor to maximize their labor productivity, they need to start with clear information provided to the crews doing the actual installation. Good information is the first of the six pillars of productivity and means several things:

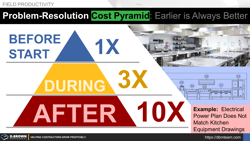

design field operations productivity project management virtual constructionProblem-Resolution Cost Pyramid - Earlier is Always Better

An easy way to visualize the cost of problem resolution at different stages of construction is with this pyramid. The cost of the problem is the cost of the problem (1X). Finding it ahead of time minimizes the costs and maximizes customer satisfaction.

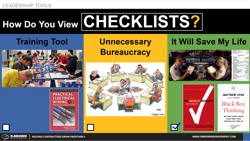

change management field productivity project managementUsing Checklists Effectively

Too many construction businesses needlessly run on razor-thin margins due to poor productivity. Checklists are a very simple and powerful tool that can be used to mitigate many of these problems.

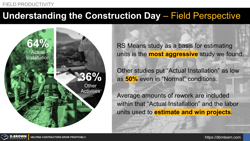

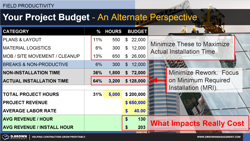

Understanding the Construction Field Day

For a contractor to truly improve their field productivity, they must start with understanding how the time is spent. Depending on the trade, project, and the labor, study the time spent on actual installation ranges from 50-64%.

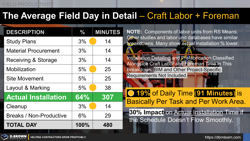

estimating field productivityThe Average Field Day in Detail (Craft Labor + Foreman)

Labor is often the biggest cost variable on a construction project. Just over half the field hours are related to actual installation. Understanding how time is spent on average in the field is the first step to improving field productivity.

estimating field productivity labor productivityConstruction Labor Budget - Alternate Perspective

Improving craft labor productivity in construction will significantly reduce risk while providing a long-term competitive advantage for the contractor and every team member. This alternate labor budget perspective shows different opportunities.

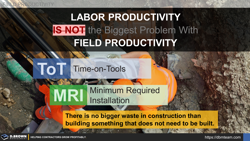

Time-on-Tools and Minimum Required Installation

Labor productivity IS NOT the biggest problem with field productivity. Under similar conditions the variation in how fast two crafts people actually “turn wrenches” is about 2X but there are far bigger problems to tackle. Focus on these three areas.

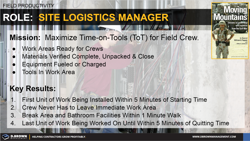

field productivity foreman training labor productivitySite Logistics Manager

About 20% of the field labor hours are spent on material logistics and daily mobilization, demobilization to the work area. What if you could shift 5% of the time spent on logistics to installation while accelerating your foreman development?

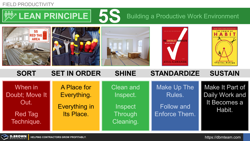

Lean Principle - 5S Habits for Building a Productive Work Environment

5S is a foundational concept for creating a productive work environment and continuous improvement. The 5S process is to productivity what eating a healthy breakfast and exercising is to your health - daily consistency will change your life.

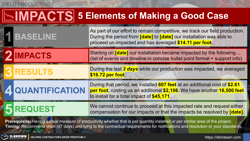

field productivity lean constructionImpacted Productivity - Five Elements of Making a Good Case

Contractors are continually faced with costly impacts to their labor productivity and schedule with many beyond their direct control. The best Project Managers know how to identify, communicate, and mitigate these impacts.

business management change management foreman training labor productivity negotiating project managementImpacted Productivity - Highly variable Labor Scheduling (Level Your Schedule)

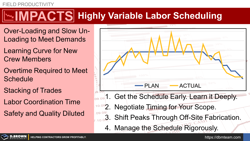

The biggest risk for a specialty contractor is the performance of on-site labor. One of the biggest impacts to labor productivity is having a schedule that requires large variations in labor.

change management claims estimating field productivityImpacted Productivity - Dilution of Management

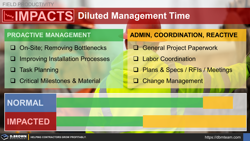

Dilution of management will compound an already impacted construction project. It is important for teams to realize the full costs of impacts as they start to occur.

change management claims field productivityImpacted Productivity - Stacking of Trades and Installation Efficiency

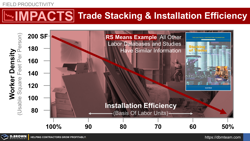

Each craftsperson needs about 200 usable square feet for a productive installation. This assumption is included in production units used to estimate and budget projects. Having less than that can impact productivity up to 50%.

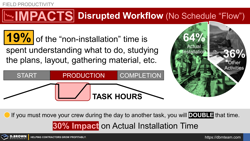

change management claims estimating field productivityImpacted Productivity - Disrupted Workflow (No Schedule "Flow")

One of the biggest impacts to productivity in construction is when tasks cannot be completed as planned. When this happens frequently, it starts to impact every aspect of the contractor’s scoreboard in a negative way starting with customer satisfaction.

change management labor productivity project managementImpacted Productivity - Fighting Back

Fighting back effectively against labor productivity impacts will significantly improve project outcomes including customer satisfaction if handled properly. There are four interrelated aspects to effectively fighting back.

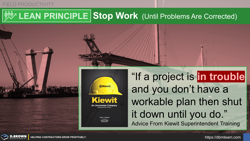

change management claims field productivity impactsLean Principle - Stop Work (Until Problems Are Corrected)

All construction projects will run into some degree of problems. It is how the project team chooses to manage these problems that ultimately determines the outcome of the project.

field productivity lean constructionProduction Tracking - Having Fun and Winning

Contractors will get the most out of their teams by building a culture around the fun of the construction game and how fun playing a game is and how good winning feels. How fun are you making your projects?

Production Tracking - Troubleshooting Problems

Implementing production tracking without a program to ensure effective troubleshooting of the problems will be minimally effective. Look at this in two major stages.

Production Tracking - Building Talent Faster

In 2018 a contractor’s primary growth constraint is available talent. At the craft and field supervision level there are plenty of people available; the constraint is about attracting them to the industry and training them.

Production Tracking - The Basics

Schedule + Production are two foundational key results the Foreman will achieve through their planning. The heart of any production measurement is simply “Earned Budget vs. Actual Cost”.

budget management labor productivity production tracking project management schedule management technologyProduction Tracking - Changing the Language

Your productivity will start to really improve as it becomes a culture and not just a tracking system. You will first notice this as a change in language in the field and across the whole project team.

Production Tracking - 5 Key Decisions

Implementing or refining a production tracking system in construction requires 5 key decisions. These decisions vary by project and task. They change as each project team evolves their approach towards productivity improvements.

Production Tracking - Doing the Math as a Habit

Today contractors have amazing tools for tracking field production such as Rhumbix. We spend a lot of time developing very tightly integrated systems with our clients focused on production feedback.

Production Tracking - Total Daily Production

Look at productivity as a daily “Jar” where your objective is to pack as much “Earned Value” into it as possible. Look at your costs in three major categories and focus on tracking what matters the most.

Production Tracking - Lessons Learned

Look at productivity as a daily “Jar” where your objective is to pack as much “Earned Value” into it as possible. Look at your costs in three major categories and focus on tracking what matters the most.

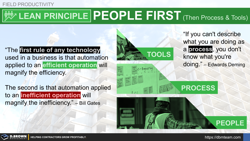

Lean Principle - People First (Then Process and Tools)

To optimize productivity, a contractor must focus on their people first, then processes and tools including technology as an integrated management system with a hierarchy. This is not a linear process: S.M.A.R.T. Experiments + Continuous Improvement.

field productivity lean construction talent development technologyProduction Tracking - Don't Be a Dry Monkey

Put a few monkeys in a cage with a ladder that has bananas on top. One monkey immediately goes for the bananas. Cold water sprays on the others. Don't let anyone on your team be a dry monkey when it comes to production tracking or schedule management.

Talent - Sustainably Integrating the 4 Priorities

When assessing the strategic importance of investing in your talent acquisition and development processes at the field leadership level it is important to understand the depth of the talent shortage over time.

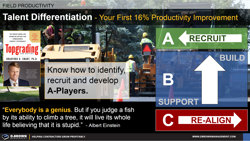

Field Productivity - Talent Differentiation

Contractors can improve their field productivity significantly just through deliberate talent management processes. While the process of continuous forced differentiation seems harsh it is actually the kindest thing you can do for everyone on the team.

Talent Development Quote - Jack Welch

From 1981 through 2001 under CEO Jack Welch, GE’s market cap (value) grew 18% compounded annually from $14B to $410B. A large part of this profitable growth was due to the rigor placed on their talent development processes directly from the CEO.

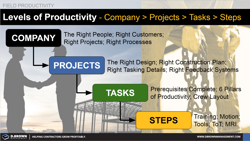

TalentLevels of Productivity

Making major improvements to labor productivity for contractors starts at the company level and must be rigorously managed all the way down to the individual steps in each task.

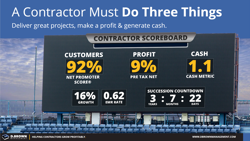

The Contractor Scoreboard - A Contractor Must Do 3 Things

This outcome-based scoreboard keeps everyone focused on what matters. Avoid metric overload and diffusion of resources. All other metrics throughout all levels of the organization fall into a hierarchy below these with priorities changing over time.

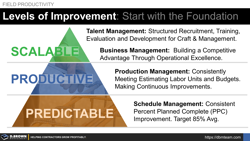

business management business planning cash flow metrics scoreboard successionLevels of Improvement: Start with the Foundation

Every process in your business including field productivity will go through three levels of improvement: From predictable to productive to scalable. Trying to skip levels is the surest way to slow down improvements across the company.

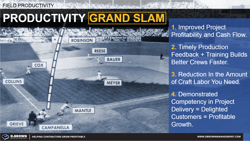

business management labor productivityField Productivity Grand Slam

When contractors are truly successful at improving their field productivity it is like Mickey Mantle’s pivotal Grand Slam during game 5 of the 1953 World Series. The bases are loaded. You are at bat. The Big Four productivity home runs:

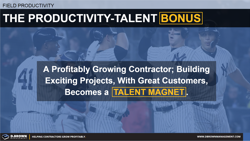

The Productivity-Talent Bonus

Contractors will receive a major talent bonus when they put a relentless focus on field productivity. They will become “Talent Magnets” for the best in the industry making them unstoppable even in the face of major talent shortages.

Market Forces - Surviving vs. Thriving

Construction contracting is a highly competitive business in a rapidly changing market. The “Invisible Hand” of the market is constantly demanding that construction projects are delivered:

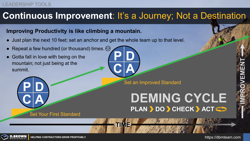

Continuous Improvement: Plan, Do, Check, and Act (PDCA)

Improving productivity in construction is exceptionally challenging. It must be embraced as a journey and not a destination. It must be made into a game so that people clearly see what winning looks like and fall in love with the process.

field productivity lean construction management